An estimated 1 in 9 men will be diagnosed with prostate cancer, the second leading cause of cancer-related death in men in the U.S. The American Cancer Society estimates that there were 192,000 new cases last year, 33,000 of which will be fatal. The most effective way to survive prostate cancer is early treatment, which engineers made more accurate and efficient with pneumatics.

While taking biopsies, surgeons currently use ultrasound to image the prostate and an MRI to detect and target the most aggressive parts of the tumor sites. This means that a urologist needs to make randomized systematic biopsies using ultrasound.

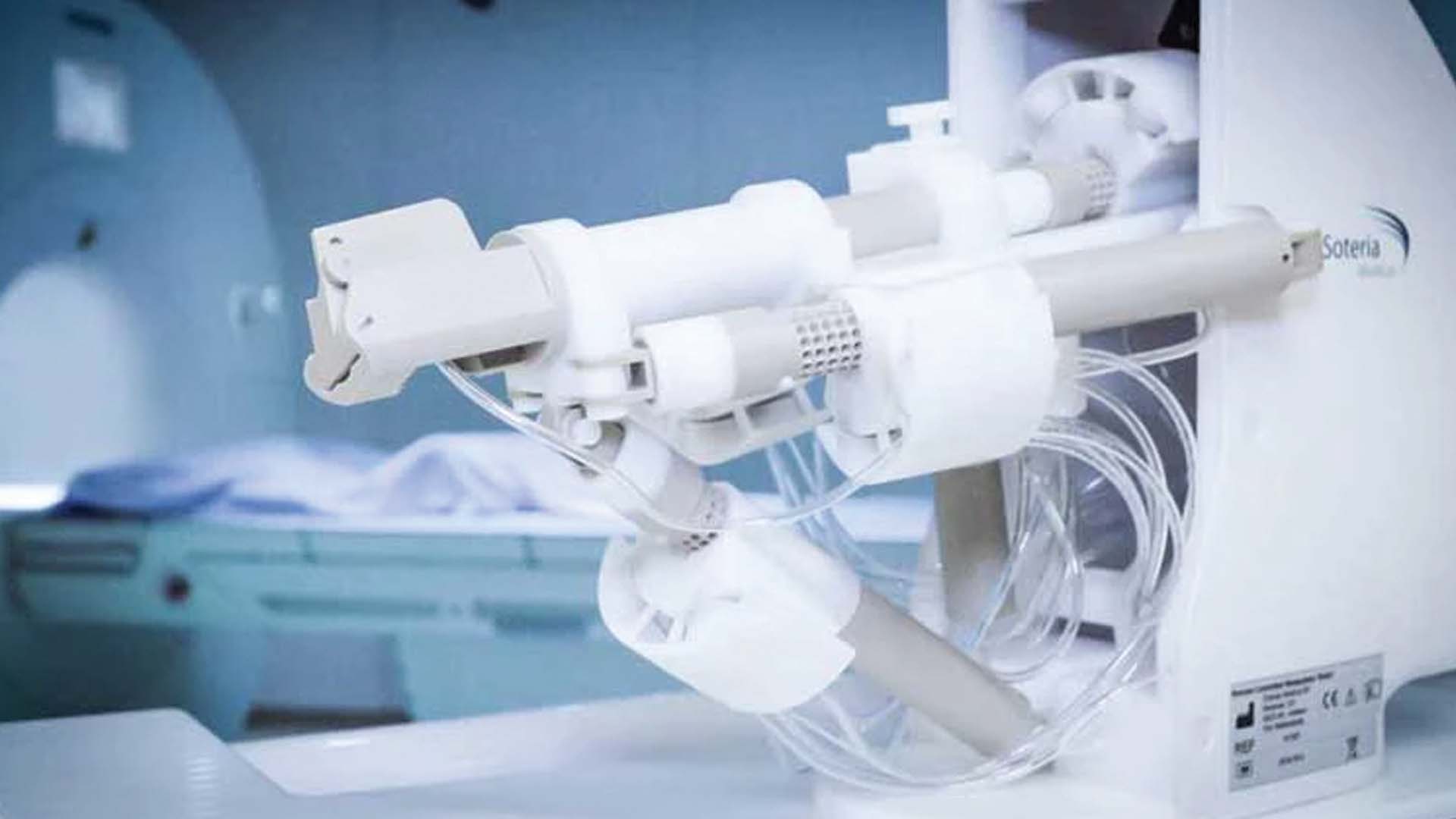

In order to make diagnosing prostate cancer quicker and more accurate, engineers at Soteria Medical BV wanted to design a Remote-Controlled Manipulator that could use a surgeon-controlled robot to accurately sample the suspicious areas of the prostate with a biopsy probe. This procedure takes place inside an MRI machine, allowing surgeons to watch the prostate and probe in real-time.

However, metal interferes with MRIs and the robot had to fit inside the machine. The solution? Pneumatic power. Pneumatics, which is how air pressures, powers, and moves something, allows the robot to work efficiently without using metal. Furthermore, the lack of metal makes the robot small enough to fit inside of the MRI.

The pneumatic actuators and controls can position and move the probe. The probe is then connected to the MRI control unit with over 20 feet of pneumatic tubing.

The robot and its use of pneumatics speed up the biopsy procedure and make it more precise, resulting in lower costs and lower stress for the patient.

To find out more about the future of pneumatics, stream Tomorrow’s World Today’s “The Power of Air” on SCIGo and Discovery GO.

Discover World of Innovation, and discover the science behind exercise, how recycled art turns trash into treasure, and what you need to know about electronic recycling.