New technology is shaping the toy industry by making manufacturing more efficient and the toy playing experience more immersive.

Modern smart toys, designed to provide a more immersive experience, often feature artificial intelligence (AI), Bluetooth connectivity, and sensors. These could include toys such as educational tablets that adapt to a child’s learning pace or robotic animals that can respond to voice commands.

Additionally, augmented reality (AR) and virtual reality (VR) create an immersive and imaginative game environment. AR-enabled toys overlay digital or virtual content into the real world, whereas VR devices create immersive digital worlds that users can interact with and play, learn, explore, etc.

AI allows a new level of customization of the toy-playing experience. Algorithms can analyze individual preferences and adjust a toy’s features and responses accordingly. Toys powered by AI can respond to voice commands, recognize patterns, and even develop ‘personalities’ that evolve over time.

CogniToys’ Dino, for example, uses AI to understand and respond to a child’s questions and statements, hold conversations, and adapt to a child’s communicative needs and level of understanding.

Spin Master, for example, created an interactive digital pet called Bitzee that you can touch because it’s made out of a flexible printed circuit board with capacitive touch centers. In addition to being tactile, each Bitzee pod comes equipped with 15 characters that mature at different rates based on how you take care of them.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

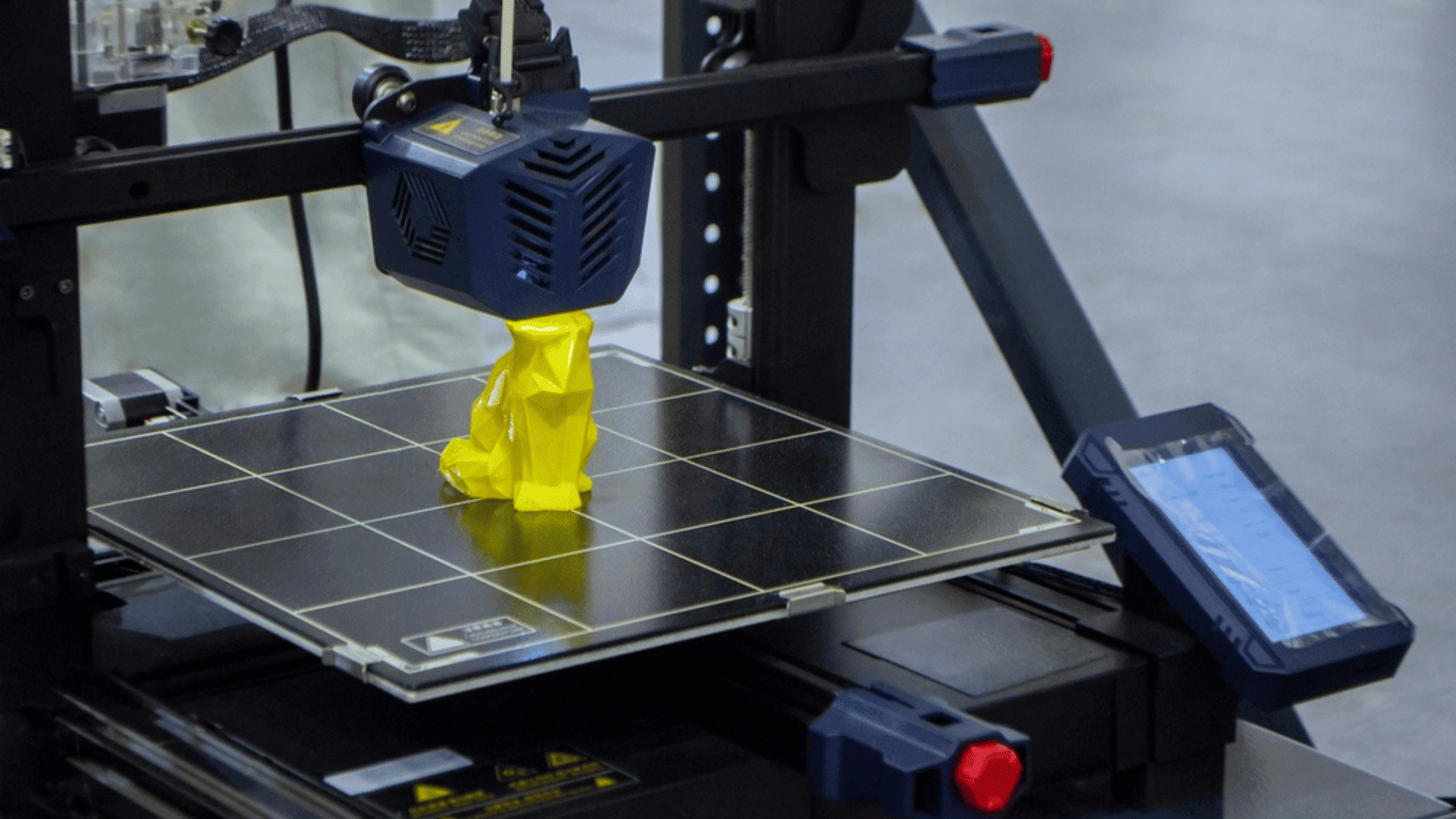

New technological changes in the toy industry’s supply chain dynamics have resulted in industry growth, including IoT, 3D printing, autonomous vehicles, mobile connectivity, etc. Advancements in technology have enabled companies to enhance their supply chain operations by improving efficiency, reducing costs, and increasing visibility.

Introducing more automated systems can accelerate the production process while diminishing errors. Robot systems are capable of performing repetitive tasks with precision and speed unattainable by humans.

Additionally, toy-making machines are becoming more advanced by incorporating AI and machine learning algorithms to make the process more efficient. Advanced software powered by AI algorithms can analyze market trends and consumer preferences, allowing toy manufacturers to enhance their design and prototyping capabilities by giving them insights into their consumers’ changing needs. These insights allow toy companies to be proactive and create toys that are more likely to appeal to their target demographics.

LEGO has integrated an AI-powered tool that predicts how certain pieces will fit together and suggests efficient ways to achieve design goals. The tool allows LEGO designers to quickly prototype new sets and themes, significantly reducing the time and resources required to create a new product. Robots and automated systems also handle the packaging and sorting of LEGO blocks, which has significantly improved efficiency.

Technology also plays an important role in the quality and safety of toys. AI-powered systems inspect toys at various stages of production for potential safety risks or defects. The efficiency and accuracy of these advanced systems ensure that only products meeting the highest safety standards are released to the public.

Tune in to the Science Channel to watch Toys of Tomorrow at 10 AM EDT on Saturday, June 1!