Innovation and production collide at Toyota Logistics Services (TLS) in Long Beach, California. The first-of-its-kind “Tri-gen” system uses biogas to generate renewable electricity, renewable hydrogen, and usable water. This approach revolutionizes vehicle processing operations at Toyota’s Port of Long Beach facility by allowing the facility to run on renewable, on-site generated electricity. In addition, it serves as a scalable model for reducing emissions for various industries.

Tri-gen

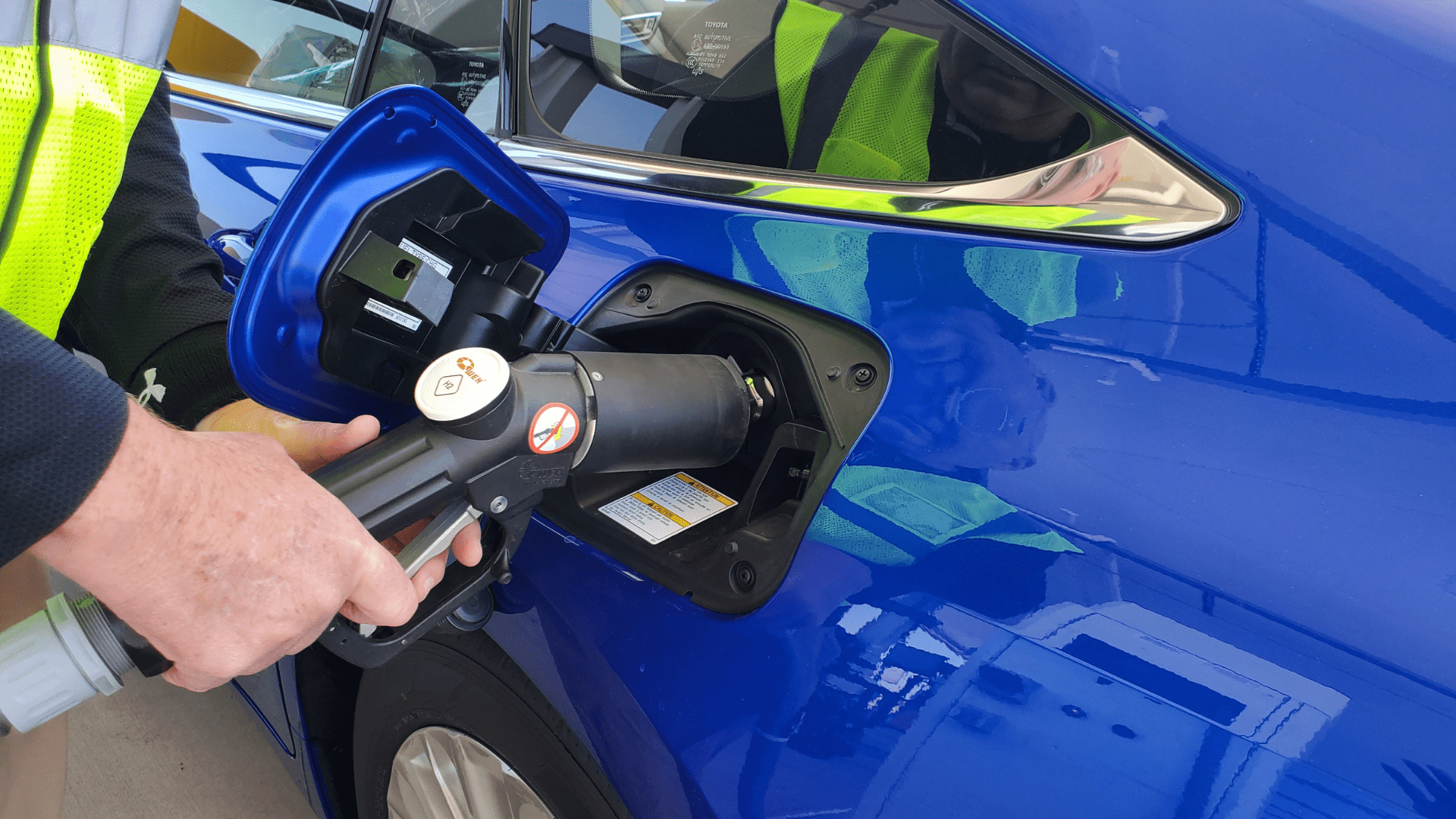

As Toyota Logistics Services looked to redesign its facility, it teamed up with FuelCell Energy, Inc., to support significant changes in its operations. Toyota has researched and developed fuel cells that power its Mirai vehicles and for other applications, so it knew that FuelCell Energy’s large-scale molten carbonate fuel cell system that runs on hydrogen (but is also capable of producing hydrogen) could be a great fit at TLS.

“The goal of our collaboration with FuelCell Energy was to find sustainable solutions for the TLS vehicle processing facility here at the Port of Long Beach as part of our goal to remove carbon dioxide emissions from our operations,” said Group Vice President of Sustainability and Regulatory Affairs at Toyota, Tom Stricker. “This groundbreaking facility shows that there are ways to reduce our emissions and burden on natural resources with scalable technology based on hydrogen.”

Thanks to Fuelcell Energy’s Tri-gen platform, TLS Long Beach is Toyota’s first port vehicle processing facility powered by 100 percent on-site generated renewable electricity. The innovative fuel cell technology uses an electrochemical process that converts directed renewable biogas into electricity, hydrogen, and usable water. The highly efficient, combustion-free process emits virtually no air pollutants.

Using Renewable Energy

The three products generated at Tri-gen are all used at Toyota’s Port of Long Beach. Tri-gen can produce 2.3 megawatts of renewable electricity, part of which supports TLS, while the excess electricity goes to the local utility, Southern California Edison.

Tri-gen can also generate up to 1,200 kg/day of hydrogen for Toyota’s fueling needs. This includes fueling Toyota’s fuel cell electric vehicle (FCEV) Mirai processed at TLS. Tri-gen can also supply hydrogen to the adjacent heavy-duty hydrogen refueling station to support TLS logistics and drayage operations at the port.

Finally, the water byproduct of hydrogen generation can generate up to 1,400 gallons of usable water per day. This water is repurposed for TLS car wash operations for vehicles that come through the port before they’re sent out to customers. According to Toyota and FuelCell Energy, it helps reduce the demand on the constrained water supply by about half a million gallons per year.

“The dawn of the renewable hydrogen era is upon us, thanks to our collaboration with Toyota and FuelCell Energy and their innovative Tri-gen system,” said Port of Long Beach CEO Mario Cordero. “The green power generated by the Tri-gen system and similar projects is part of our multi-layered strategy to fuel our goal to become the world’s first zero-emissions Port.”