Toy manufacturers are attempting to limit the industry’s environmental impact by incorporating sustainable practices into the materials, manufacturing, and recycling of toys.

One way companies attempt to limit their environmental impact is by making toys from eco-friendly materials. For example, some companies create classic kid’s boat and truck toys using 100 percent recycled or upcycled materials, such as old milk jugs.

Still others are creating toys out of wood certified by the Forest Stewardship Council (FSC) and was sustainably harvested. They will also incorporate non-toxic or organic paints, dyes, or water-based finishes. Determining the best materials for each product involves mechanical and chemical testing to validate safety and product quality.

Some companies also create toys using the byproducts of other processes to save on resources. PlanToys, for example, harvests its own sawdust and makes additional toys from what it calls PlanWood. Tender Leaf Toys creates toys from reclaimed rubberwood, a by-product of latex manufacturing.

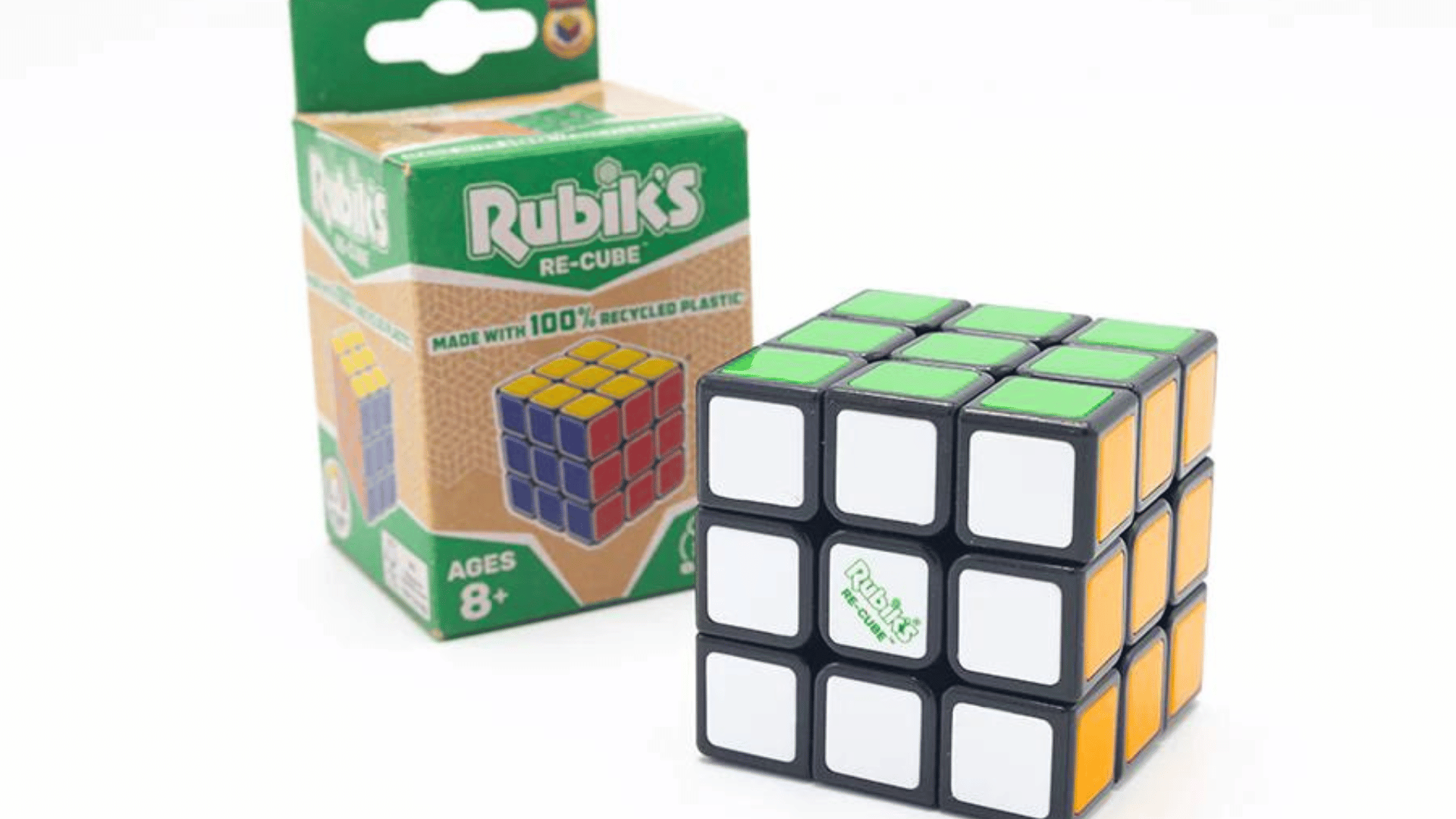

Spin Master also created the Rubik’s Re-Cube which is a Rubik’s Cube redesigned using 100 percent recycled materials. Originally made with virgin acrylonitrile butadiene styrene (ABS), the Re-Cube is made with recycled ABS.

U.K.-based plastic injection molder Adreco Plastics says the versatility of petroleum-based thermoplastic ABS makes it popular in several industries. ABS can be easily molded, sanded, and shaped, and it takes color easily, which allows finished products to be dyed in exact shades for project specifications. ABS also has no appreciable quality degradation after being melted and re-extruded, which allows it to be recycled.

The Re-Cube is not Spin Master’s first sustainable toy project; it also has its Mindful Classics collection. This includes games with pieces made from recycled plastic such as Chess & Checkers and Four in a Row. The recycled materials in those games eliminated the need for 55,000 pounds of virgin plastic.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

Toy manufacturers are also making their processes more sustainable by altering the packaging designs to ensure they’re 100 percent recyclable by using recycled and/or recyclable cardboard or plastic. This has been a large industry focus for several years, including companies such as Mattel, Hasbro, and Lego, as well as initiatives such as removing plastic windows from blister packaging.

The toy industry is also becoming more sustainable by finding new and creative ways to recycle toys. Spin Master, for example, recycles their toys to create more play opportunities.

Consumers can send back their previously loved toys through Spin Master’s Terracycle program. When recycled, Spin Master’s toys are sorted at TerraCycle based on their composition and characteristics, such as size separation, optical sorting, sink/float, air density, gravity, magnetic, etc. The plastic is then cleaned and sent to third-party partners to be reprocessed into pellets, flakes, or powder for use other goods like park benches, decking, and playgrounds.

Tune in to the Science Channel to watch Toys of Tomorrow at 10 AM EDT on Saturday, June 1!