Researchers from the University of Cambridge and the University of California, Berkley, developed a solar-powered method to produce hydrocarbons, which are molecules made up of hydrogen and carbon. A key benefit of hydrocarbons is their ability to produce cleaner alternatives to fossil fuels. According to the researchers, it’s a practical way to produce hydrocarbons powered solely by the Sun.

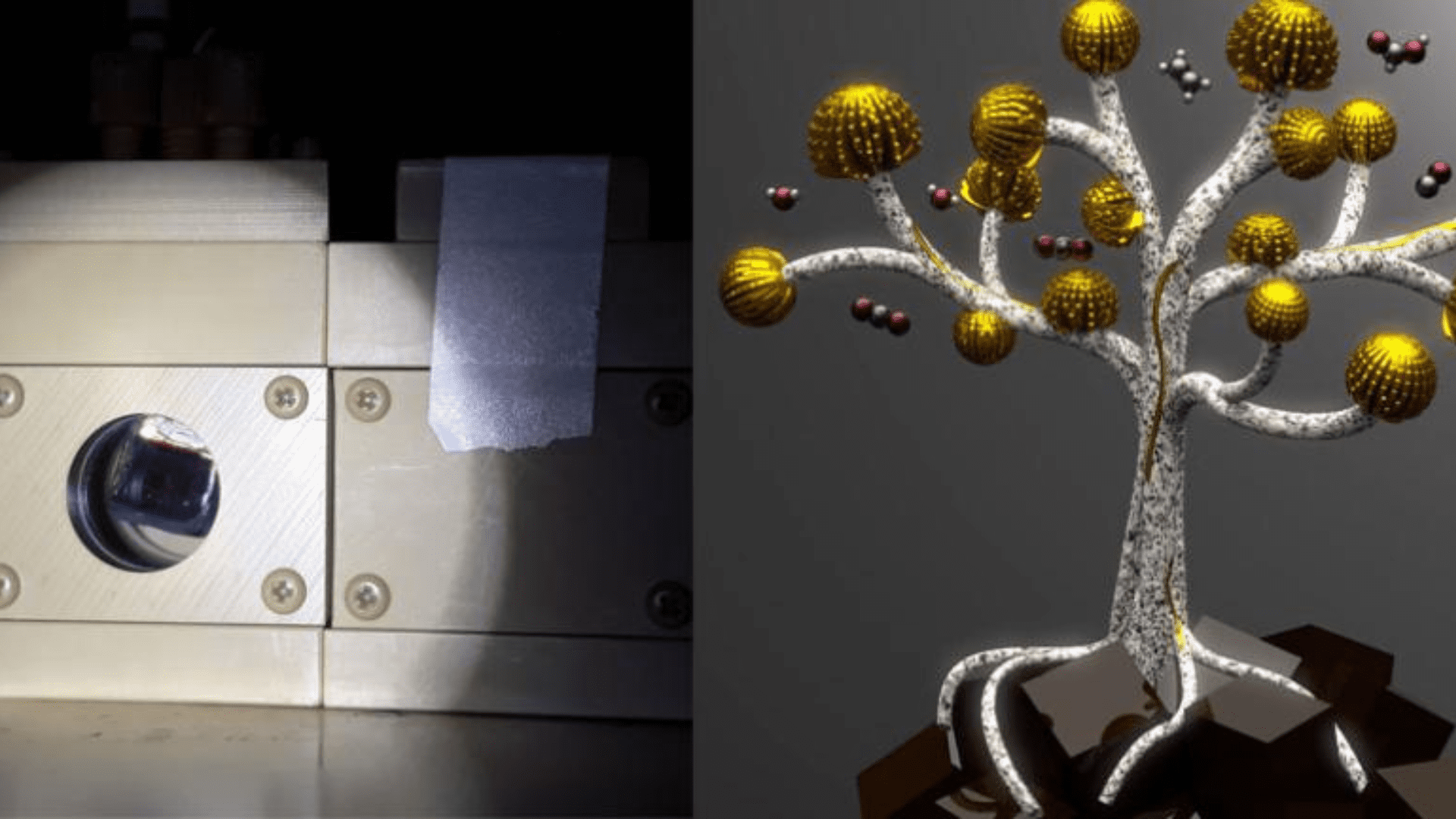

Their device combines a perovskite-based solar cell with a copper nanoflower catalyst. Perovskite is a calcium titanium oxide mineral commonly used in solar cells. Nonetheless, copper nanoflower catalysts are different from typical metal catalysts. Unlike traditional metal catalysts, the copper nanoflower catalyst converts carbon dioxide into more complex hydrocarbons like ethane and ethylene, which are essential for fuels, chemicals, and plastics.

Turning CO2 into Clean Energy

This groundbreaking method uses CO2, water, and glycerol to produce clean energy, avoiding any extra carbon emissions.

The study expands on the team’s previous work on artificial leaves from 2022, which was inspired by the photosynthesis process. “We wanted to go beyond basic carbon dioxide reduction and produce more complex hydrocarbons, but that requires significantly more energy,” said Dr. Virgil Andrei from Cambridge’s Yusuf Hamied Department of Chemistry, the study’s lead author.

When the researchers combined a perovskite light absorber with a copper nanoflower catalyst, it produced “more complex” hydrocarbons. Then, they added silicon nanowire electrodes to oxidize glycerol instead of facing the challenges of splitting water. According to the researchers, this process is 200 times more efficient than systems for splitting CO2 and water.

In addition to boosting CO2 reduction performance, the researchers say it produces high-value chemicals such as glycerate, lactate, and formate, which are often applied in pharmaceuticals, cosmetics, and chemical synthesis.

“Glycerol is typically considered waste, but here it plays a crucial role in improving the reaction rate,” said Andrei. “This demonstrates we can apply our platform to a wide range of chemical processes beyond just waste conversion. By carefully designing the catalyst’s surface area, we can influence what products we generate, making the process more selective.”

Looking ahead to the future, researchers want to improve the current CO2-to-hydrogen efficiency, which is around 10%. They say they want to open the doors for innovation in sustainable chemical production, with hopes of applying their platform to “even more complex organic reactions.”