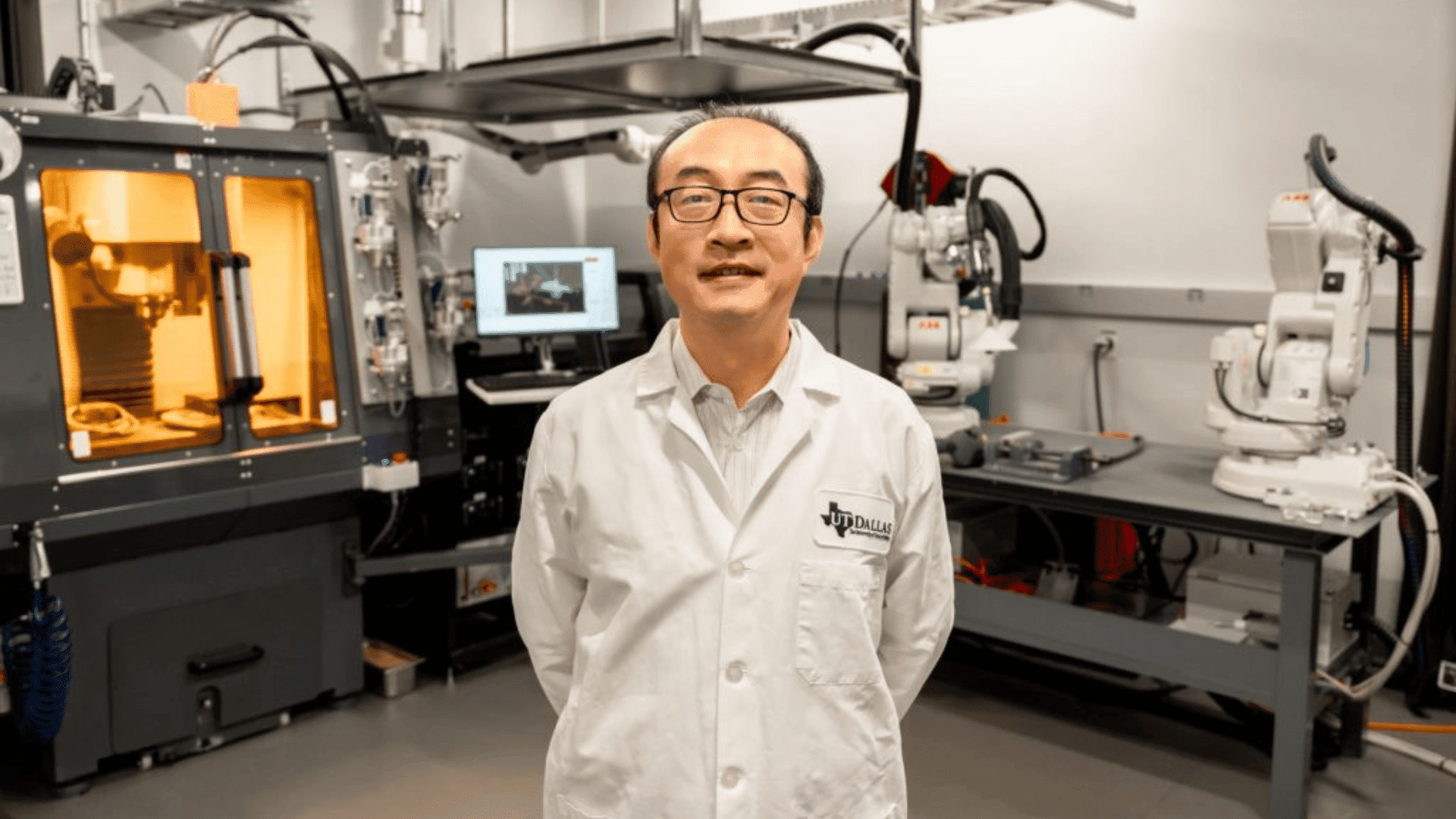

Given the dramatic temperature fluctuations, weaker gravitational pull, and almost total absence of atmosphere – building settlements on the Moon involves a series of engineering challenges. To help solve this problem, scientists like Dr. Wei Li at the University of Texas at Dallas created a virtual lunar welding tool to solve assembly issues for large constructions on the Moon.

Lunar Welding

Welding is a metal-joining process that’s essential for building large structures in space, such as research facilities, habitats, living quarters, etc. However, welding on the Moon could cause defects that weaken critical structures.

“As we try to return to the Moon and reach Mars, keeping astronauts safe while achieving the missions is very important,” said Dr. Edward White, professor and department head of mechanical engineering and holder of a Jonsson School Chair. “Being in Earth’s orbit is a lot easier knowing that when things go wrong, we can make repairs and return safely. I’m really excited that Dr. Li’s research will help play an important role in making space travel safer and will enable us to successfully complete space missions.”

To combat these issues, scientists created a virtual environment that simulates the precise conditions of the Moon’s surface. The virtual lunar welding program uses multiple-physics modeling to simulate welding and the resulting joint strength. It also utilizes metal additive manufacturing technology and a custom-built directed energy deposition machine.

This platform allowed his team to test and troubleshoot various welding techniques on the Moon without the risks and costs involved in a real space mission. A few of the techniques tested included electron beam, laser, and electrical arc welding.

The team hopes that this type of testing will allow them to identify potential defects and optimize the welding process with maximum strength and reliability. They also believe that this type of process and material optimization could also be used with fused deposition modeling in space. This may enable on-demand repair and fabrication, which would reduce the reliance on Earth supplies.

Recognizing the importance of this research, NASA has awarded Dr. Li an Early Stage Innovations grant.

“It would be very hard to establish regular machine shops on the Moon’s surface to manufacture metal structures as we do on Earth,” Li said.

“However, it could be possible to use spacecraft to ship metal components from the Earth to the Moon, then deploy welding technology there to assemble the components into large structures that could enable the establishment of a human community.”