Although the world is currently living through a scary time, manufacturing companies are putting aside their normal practices in favor of building life-saving equipment like ventilators.

There are a few different kinds of ventilators that can be manufactured and used to help patients around the country. Some are complex and electronically made while others are simple with old-fashioned knobs and are often disposable. The price range to manufacture the simpler ones will obviously be much lower, but the electric ones have a higher rate of durability. This is all being taken under consideration by the dozens of manufacturers who have turned their sights toward creating ventilators during this critical time. They must navigate these muddy waters and balance the need for speed with the need for high-quality equipment.

Some of the efforts to supplement these diminishing supplies are coming from innovative companies such as Ford, GE, GM, and Xerox. Over the past few months, we’ve seen the largest combined effort of American manufacturers (outside of wartime) to do in weeks what would normally take medical device makers months to produce. In an interview with Forbes, Airon vice president Pamela Fry stated, “There are a limited number of manufacturers of ventilators, and each one of those manufacturers works on just-in-time manufacturing… It’s not like any manufacturer has 100–let alone 100,000–ventilators in stock.”

For companies like Ford and GM, stepping up and adjusting manufacturing priorities during a time of crisis is nothing new. During World War II, for example, Ford and GM redirected some of their manufacturing and assembly lines to make bombers and military hardware. In regard to their role, Ford’s CEO Jim Hackett stated, “I got calls from Edsel Ford, who’s on our board, his father was Henry [Ford] II. He said, ‘You know the company’s history in these crises….You’re the CEO. You know we’ve got another role to play.’”

GM has partnered with Ventec to produce portable ventilators and currently has a $489 million contract with the Department of Health and Human Services. Xerox, on the other hand, has partnered with Vortan and turned their attention toward disposable ventilators. Xerox plans to manufacture up to 1 million disposable ventilators while companies like Ford plan to create 50,000 ventilators by July 4th.

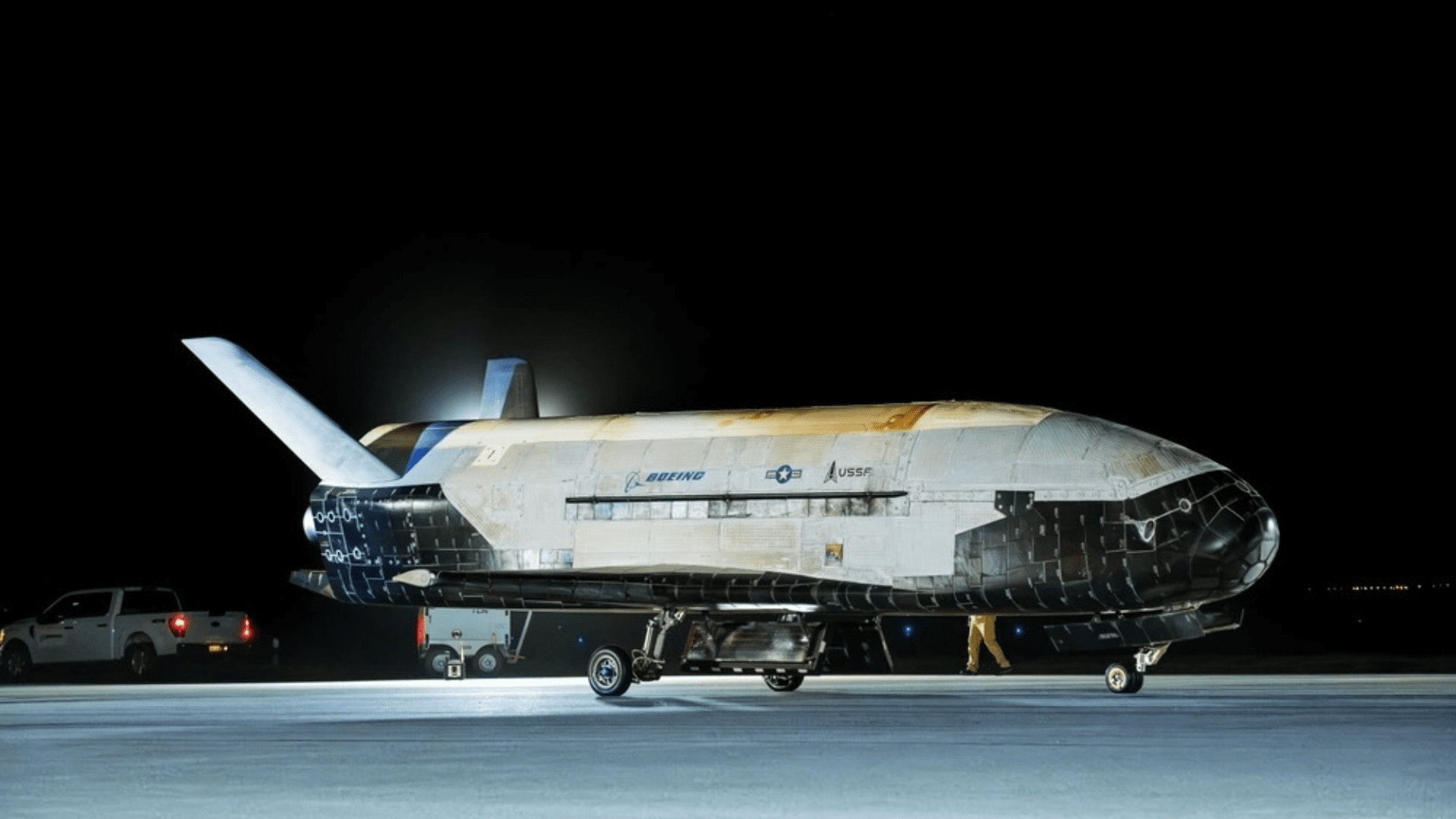

Most recently, medical device makers have formed an alliance with Google and aerospace technology in order to speed up the manufacturing of parts needed to build life-saving ventilators. The Advanced Medical Technology Association (AdvaMed) Monday confirmed plans to launch a new platform developed by the Aerospace Industries Association (AIA), Google, and others to create a more streamlined approach for ventilator manufacturing. The platform called “VentConnect,” is designed to efficiently connect companies to global suppliers for ventilators, a complex device made up of some 1,700 parts. The aerospace industry has component parts and raw materials that, though they have historically been used for airplanes or spaceships, can also be useful for ventilator production.