What’s the kind of sand you can see through? That sounds like an oxymoron- sand is gritty, dirty, and notorious for getting in whatever crevice it can. Beyond that, it’s hardly translucent. Visiting the beach during high winds is impossible because of the low visibility. So how can you see through sand? Simple. Just heat it up and make glass.

What’s the kind of sand you can see through? That sounds like an oxymoron- sand is gritty, dirty, and notorious for getting in whatever crevice it can. Beyond that, it’s hardly translucent. Visiting the beach during high winds is impossible because of the low visibility. So how can you see through sand? Simple. Just heat it up and make glass.

Glass is made of ordinary sand that has been heated to 1700 degrees Celsius (3090° F) and melted into liquid. It doesn’t cool or immediately transform back into coarse specks. Instead, it transforms completely as it changes states and becomes something new. The new product is an amorphous liquid since it has the structure of a solid but the molecular oddities of a liquid.

In a commercial setting, however, straight sand is rarely used. Instead, sand is mixed with recycled glass, sodium carbonate, and calcium carbonate. The mixture is then heated until everything melts. The sodium does lower the sand’s melting point but would make the end glass melt in water. This is why the calcium (limestone) is added, to prevent the resulting product from turning into the Wicked Witch of the West.

Once the sand is melted, the glass is typically poured into molds to create the shapes for everything from cups to collectibles. For flat sheets, the liquid mixture is poured on top of molten tin in a giant vat. Some glass is blown into unique shapes and designs by wrapping it around a pipe and rotating it. Glassblowing is an art form of itself, with amazing ornaments and vases being just some of the end results.

Of course, there are many varieties of glass beyond what’s used for windows and dishes. For the green-tinted kind, iron and chromium are added during the melting process. Pyrex and other oven-proof glassware use boron oxide to prevent cracking in the intense heat. Crystals are easily cut and can be valued for how they bend color. It’s achieved by adding lead oxide. As for bulletproof glass, it’s actually normal sheets of standard glass layered together and bonded together by plastic.

Of course, there are many varieties of glass beyond what’s used for windows and dishes. For the green-tinted kind, iron and chromium are added during the melting process. Pyrex and other oven-proof glassware use boron oxide to prevent cracking in the intense heat. Crystals are easily cut and can be valued for how they bend color. It’s achieved by adding lead oxide. As for bulletproof glass, it’s actually normal sheets of standard glass layered together and bonded together by plastic.

Windshields are one of the most common types of glass people encounter on a day-to-day basis and begin with the basic glass formula. A few extra chemicals are added, however: potassium oxide, magnesium oxide, and aluminum oxide. This mixture is melted and cooled before being cut into the proper shape. The cut is actually made with a tool coated in diamond dust, as diamond is one of the few substances on Earth tougher than glass. The cut glass is bent into shape and goes through a process called tempering. Tempering involves heating the glass to make it more durable. The windshield is laminated and attached to the vehicle it was made for.

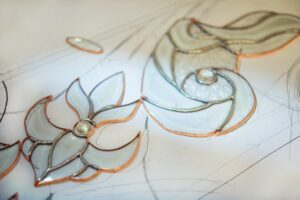

Much like the green-tinted stuff covered above, stained glass is also bursting with color. This is achieved with any number of metallic oxides, depending on what shade is desired. Stained glass windows are still crafted by hand, using many of the same techniques used when blowing glass. Of course, before any of the sand is even melted, a design must be made, and how much glass of each color is determined. The glass is prepared and cooled, then cut into the appropriate shapes and sometimes painted to create various effects. Glazing and leading come next, to add the lead that separates each segment. Everything is then waterproofed and assembled. While it’s far more time-consuming and expensive, the unique beauty of stained glass keeps it popular.

Much like the green-tinted stuff covered above, stained glass is also bursting with color. This is achieved with any number of metallic oxides, depending on what shade is desired. Stained glass windows are still crafted by hand, using many of the same techniques used when blowing glass. Of course, before any of the sand is even melted, a design must be made, and how much glass of each color is determined. The glass is prepared and cooled, then cut into the appropriate shapes and sometimes painted to create various effects. Glazing and leading come next, to add the lead that separates each segment. Everything is then waterproofed and assembled. While it’s far more time-consuming and expensive, the unique beauty of stained glass keeps it popular.

Glass has been a staple of human life since the dawn of time, with humanmade glass dating back to 3500 BC. This is unlikely to change, given how ubiquitous it is in our lives. Whether crafted by hand or created through natural means, glass is all around us. So go ahead and look out your window to see the future in a tiny speck of sand.