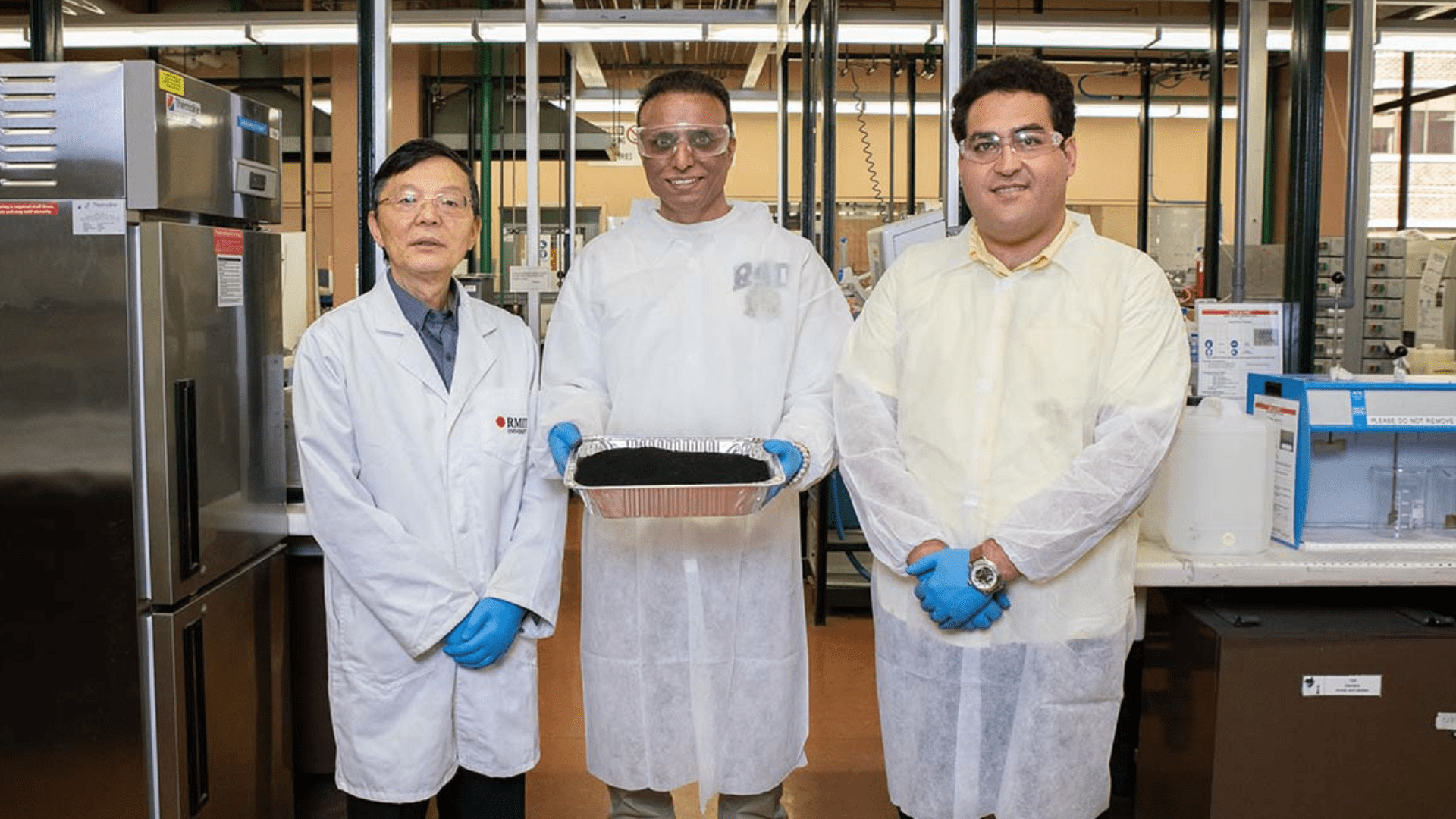

Researchers at the Royal Melbourne Institute of Technology (RMIT) are testing coffee concrete for the first time. They used it to create a walkway that’s a major step towards eco-friendly construction.

Coffee Turned Into Concrete

According to RMIT, Australia generates over 165 million pounds of ground coffee waste annually. Most coffee grounds end up in landfills, where they and other organic materials account for 3% of greenhouse emissions. Instead of letting the grounds waste away, researchers want to turn them into a valuable resource. Rajeev Roychand, a postdoctoral researcher, and his colleagues at RMIT University are committed to doing this by adding the material into concrete. However, you can’t add organic waste directly to concrete because it will decompose. When organic materials decompose, it weakens the construction. Therefore, the researchers turn to biochar.

Biochar is a solid material that is rich in carbon made from partially combusted waste material with limited oxygen. The researchers made a coffee biochar by heating the coffee waste at 662 degrees Fahrenheit without oxygen. This increases the life of the waste and makes it a suitable ingredient in concrete. Similarly, the researchers do the same thing with woodchips, another organic waste in landfills. The biochar replaces river sand in the concrete mix for the footpaths in Gisborne.

Roychand said, “Sand is getting scarce over time, and this waste can replace up to 15 percent of the sand in concrete.” Because the coffee grounds are more dense, the 165 million pounds of waste could replace 1.4 billion pounds of sand in concrete.

The world generates about 22 billion pounds of coffee ground waste annually. This can potentially replace 200 billion pounds of river sand in concrete.

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

Less Concrete Cement

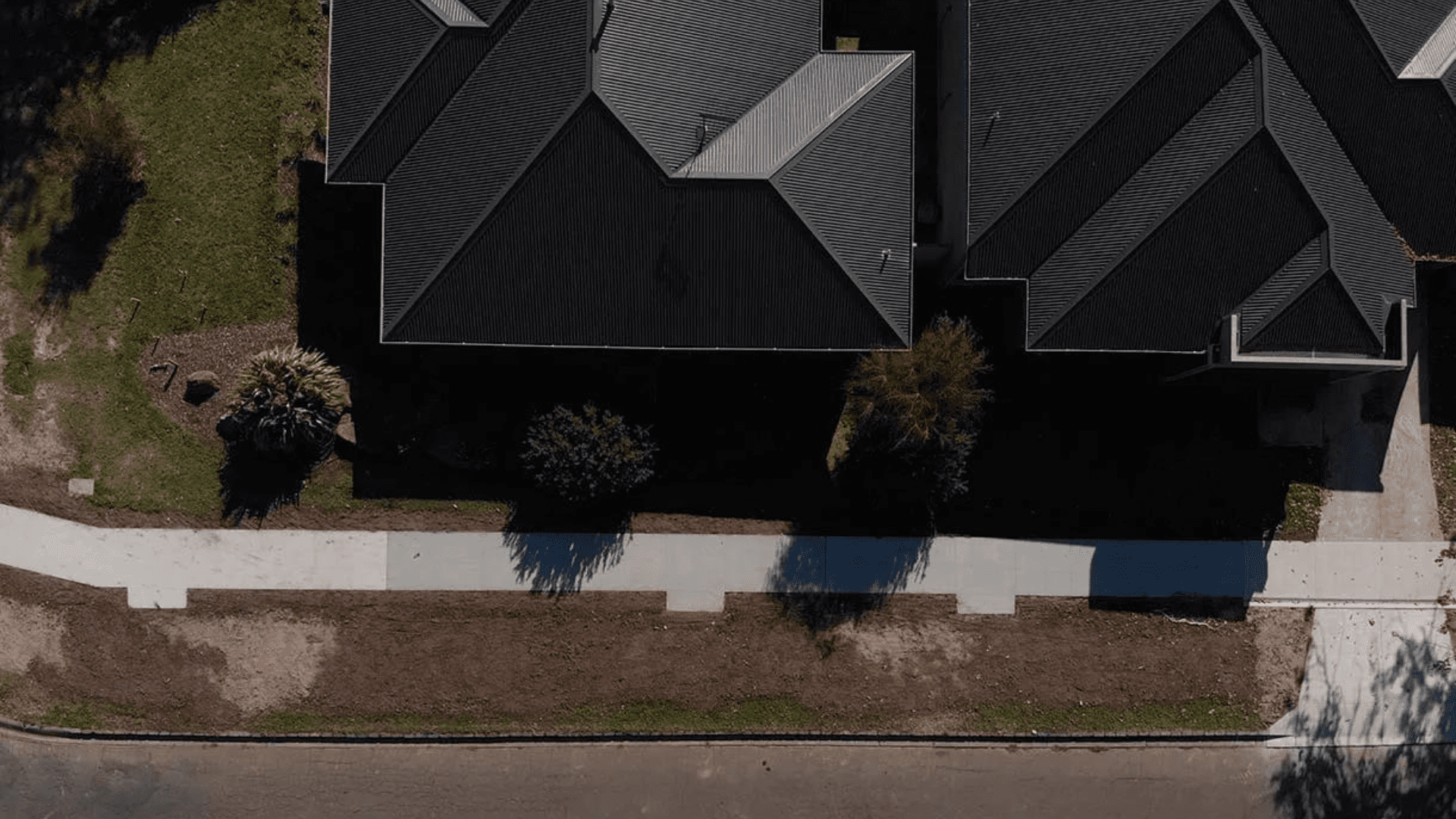

In a statement, Shane Walden, Director of Assets and Operations at Macedon Ranges Shire Council, said, “We’re taking those experiments and putting them in the ground and in the field today. We’re going to have people walking across the concrete that includes these products, and RMIT is going to be coming back and doing testing to see how they stand up.” The Macedon Ranges Shire Council is working with RMIT to develop these new footpaths.

Biochar is a step in the marathon for a greener planet, but it helps companies save money. Roychand added, “Our research creates a potential even to reduce the required cement content. Since we are achieving a 30 percent increase in strength for the coffee concrete, this could reduce the required cement content by as much as 10 percent.”

The recently constructed footpaths didn’t use less concrete; however, the RMIT researchers are working towards that goal. The carbon particle size and absorbency all vary in organic waste, but they also boost the strength of concrete.

Roychand said, “We are currently working in the supply chain sector to make this research into a mainstream product for commercial applications.”