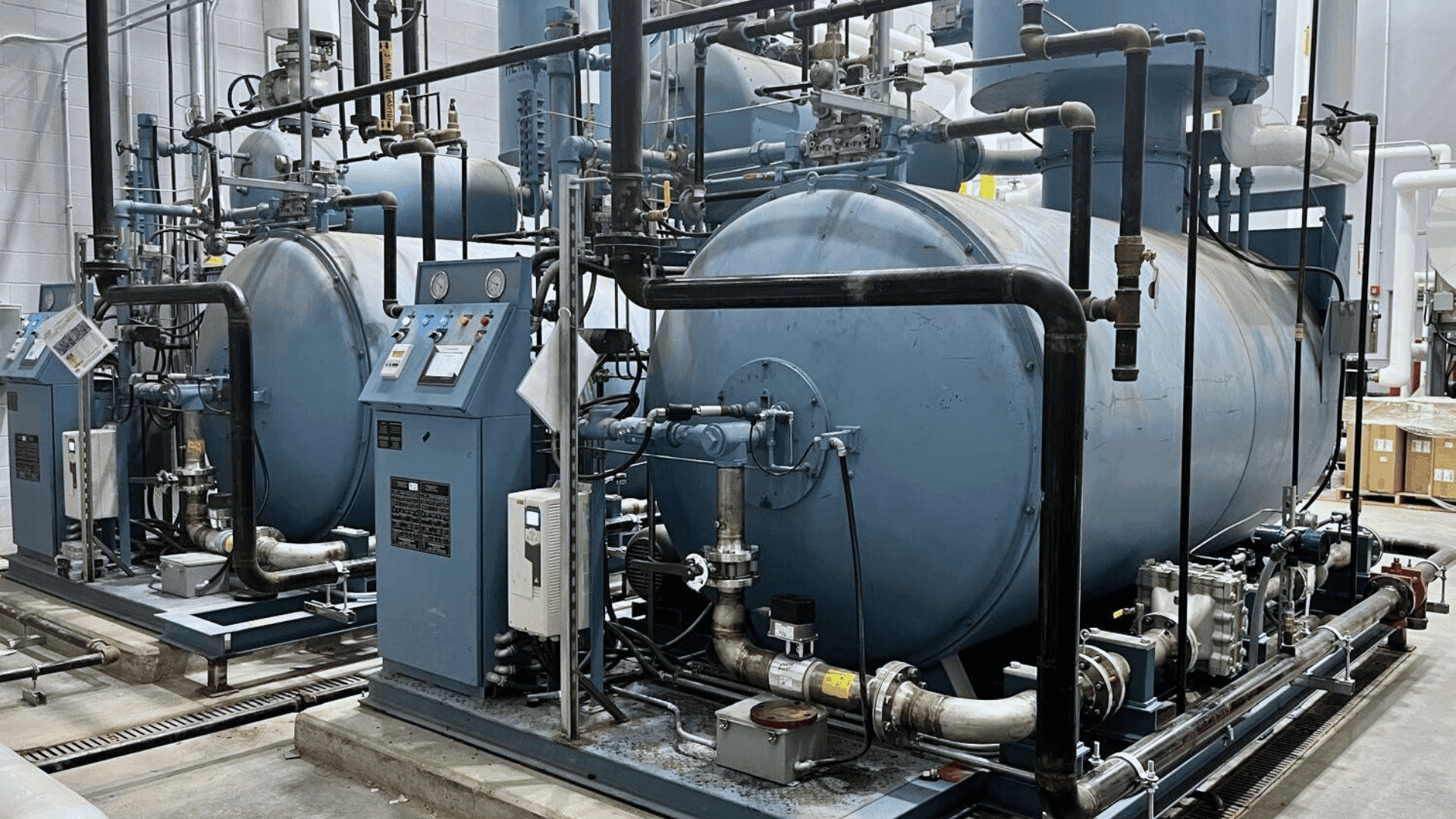

Thermogenics has unveiled a new biogas enrichment system designed to help industrial and commercial facilities significantly cut emissions and boost fuel efficiency. Tailored for sustainability-focused sectors such as food and beverage processing and waste management, the system enables boilers to run on renewable biogas—either alone or blended with natural gas—without compromising performance.

Thermogenics Unveils Biogas Enrichment System to Help North American Industrial and Commercial Facilities Cut Emissions and Improve Fuel Efficiency

New system maximizes renewable fuel use while maintaining consistent boiler output

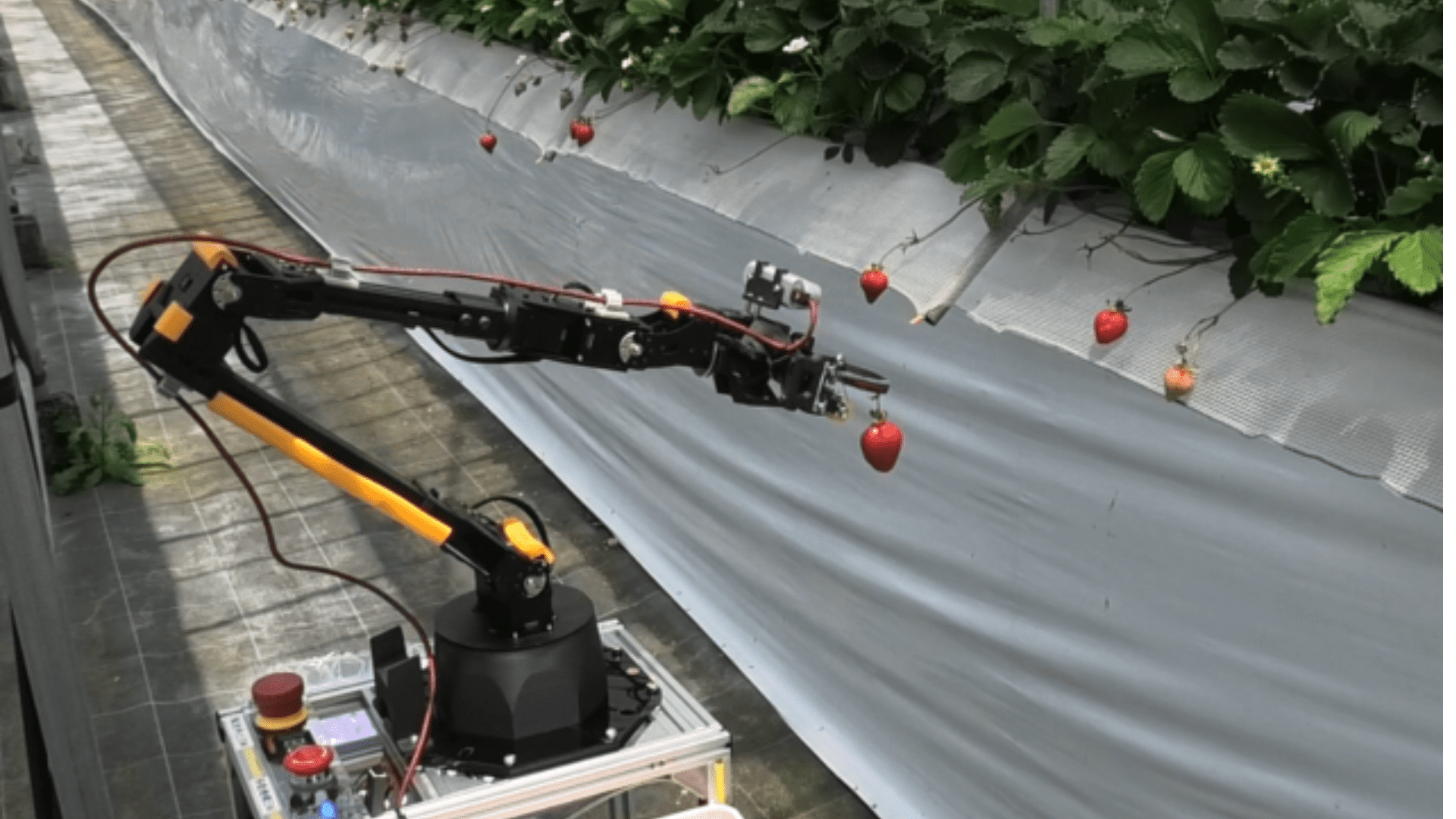

AURORA, ON, April 9, 2025 /PRNewswire/ – Thermogenics, a leading provider of boiler lifecycle solutions in North America, has introduced a new biogas enrichment system that enables industrial boilers to operate using renewable biogas (or sometimes referred to as digester gas)—either independently or in combination with natural gas. Ideal for customers in the food and beverage sector, waste management, and other sustainability-driven industries, this innovation supports efficiency goals while significantly reducing greenhouse gas emissions.

“Our systems are now operating at 500 BHP using both natural gas and biogas,” said Dean Johnson, Director of Technical Services at Thermogenics. “When properly conditioned, biogas can be a clean-burning, renewable energy source. It helps reduce emissions by capturing methane that would otherwise be released into the atmosphere. Ross Garland, CEO at Thermogenics commented, “We’re helping our customers turn waste into energy while keeping their operations reliable.”

Two Approaches. One Solution.

Thermogenics offers two tailored approaches for customers who produce digester gas:

– 100% Biogas Firing: For facilities that generate large, steady volumes of biogas—like food & beverage processing plants—Thermogenics’ systems can be configured to run entirely on renewable fuel.

– Co-Burn Enrichment: For customers with smaller or inconsistent biogas supply, the system blends natural gas with the available biogas. Thermogenics “baselines” the customer’s production (e.g. 4,000 CFH) and automatically supplements it with natural gas to maintain output, such as 500 BHP. With this co-burn system, customers can steadily use what they produce and only add natural gas to hit their required capacity.

This flexibility allows customers to extract the full value of their renewable fuel without compromising performance. That’s a win for both their bottom line and the environment.

The system is optimized for whole-plant efficiency, delivering key benefits:

– Maximizes use of renewable energy generated on-site

– Reduces reliance on fossil fuels while maintaining boiler performance

– Lowers methane emissions by capturing and combusting digester gas

– Supports ESG and sustainability targets, particularly in the food & beverage industry

– May qualify for government incentives or carbon credits in both the U.S. and Canada; eligibility varies by region.

This press release is provided for informational purposes only. TomorrowsWorldToday.com is not responsible for the content, terms, or administration of Thermogenics’ promotions. Please refer to thermogenicsboilers.com for the most accurate and up-to-date information. Tomorrow’s World Today may receive an affiliate commission if you purchase an independently reviewed product or service through a link on our website.