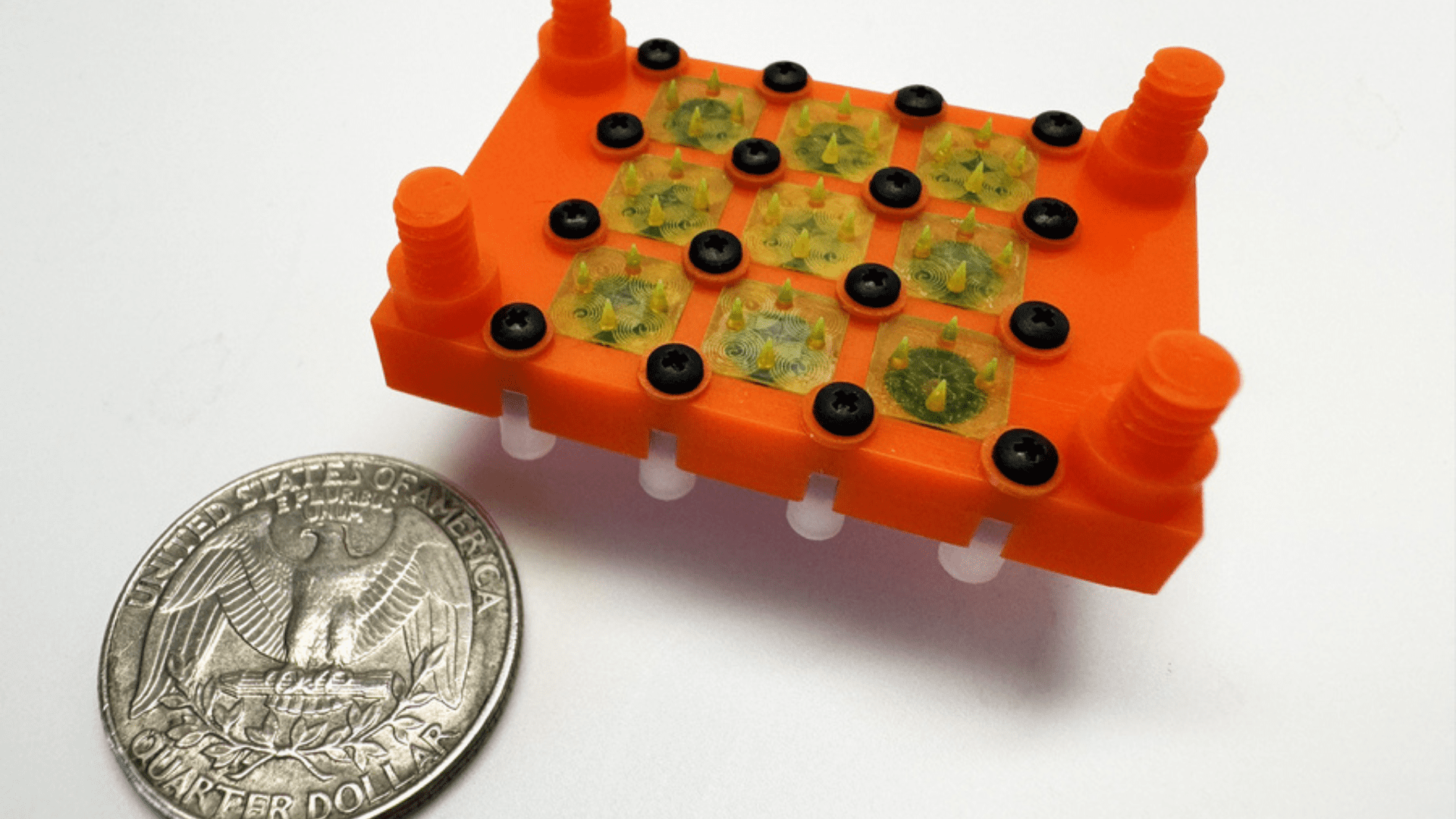

A team of MIT researchers developed a tiny, 3D-printed engine about the size of the palm of a hand. The development stems from the importance of small satellites called CubeSats. These miniature engines, called electrospray engines, are ideal for small spacecraft.

An electrospray engine applies an electric field to a conductive liquid, generating a high-speed jet of tiny droplets that can propel a spacecraft. CubeSats are becoming increasingly important and are often used in academic research. However, propelling miniature satellites is expensive, mostly because of the production process of conventional electrospray engines.

Electrospray engines utilize propellant more efficiently than powerful chemical rockets, which makes them better suited for precise, in-orbit maneuvers. The electrospray emitter generates a tiny thrust. Therefore, electrospray engines use an array of emitters that are “uniformly operated in parallel.”

Electrospray Engines

However, multiplexed electrospray thrusters are expensive and time-consuming to produce, which limits who can manufacture them and how the devices can be applied.

As a result, MIT engineers developed the first fully 3D-printed, droplet-emitting electrospray engine. Their device can be rapidly produced for a fraction of the cost, they say. Additionally, it uses commercially accessible 3D printing materials and techniques. Because 3D printing is compatible with in-space manufacturing, engineers say it could be manufactured in orbit.

The modular process combines two 3D printing methods. By developing this type of hardware, engineers overcame challenges involved in fabricating a device comprised of large and small-scale components that must work together seamlessly. Their proof-of-concept thruster comprises 32 electrospray emitters that operate together, generating a stable and uniform flow of propellant.

The 3D-printed device generated as much or more thrust as existing droplet-emitting electrospray engines. With this technology, an astronaut can print an engine for a satellite while in orbit rather than waiting for one to be sent to space.

“Using semiconductor manufacturing doesn’t match up with the idea of low-cost access to space,” said Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL). “We want to democratize space hardware. In this work, we are proposing a way to make high-performance hardware with manufacturing techniques that are available to more players.”

Velásquez-García is also the senior author of a paper describing the thrusters, which appears in Advanced Science. He is joined by lead author Hyeonseok Kim, an MIT graduate student in mechanical engineering.