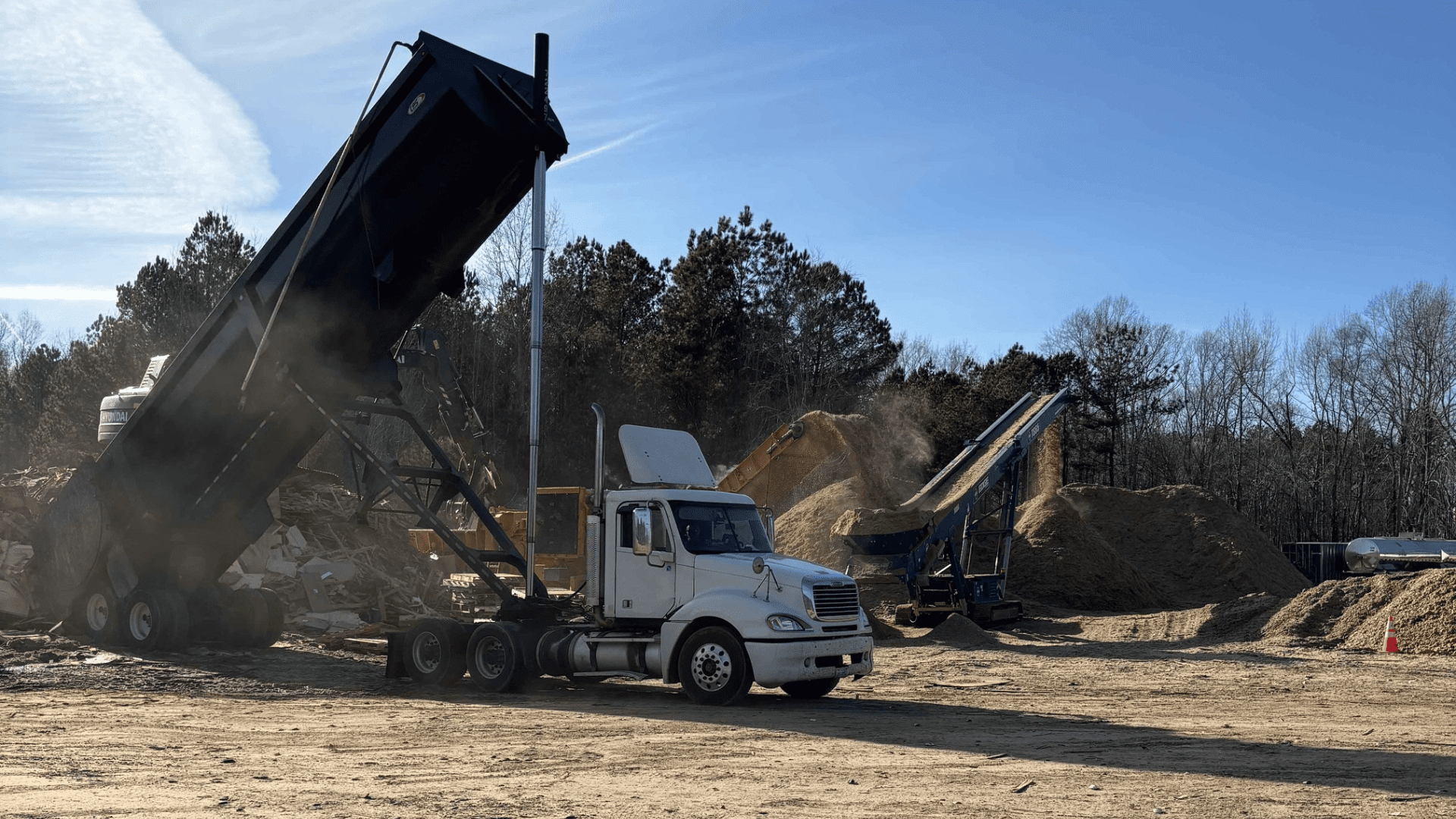

Waste management company VLS Environmental Solutions announced a new innovative recycling program that turns recycled pallets into a clean, renewable energy source. The Pallet Recycling Program is a breakthrough program that offers significant environmental and economic benefits to industries addressing sustainability efforts.

Revolutionary Recycling

This new recycling program consists of five steps. First, the VLS collects wooden pallets from various businesses and industries. Then, the metal components, such as staples or nails, are removed. After they complete those steps, the wooden pallets are shredded into sawdust. This fine sawdust goes through a process that converts it into Alternative Engineered Fuels (AEFs). These AEFs provide clean, efficient energy for industrial applications such as cement or kilns.

“Our new Pallet Recycling Program is more than just a solution—it’s an investment in a sustainable future,” said Keith Cordesman, the President of VLS. “This initiative exemplifies our commitment to finding innovative ways to help our clients reduce waste and meet their environmental objectives.”

Cordesman continued, “The initiative is for everyone. It’s a win for businesses, their communities, and the planet.”

Benefits From the Pallet Recycling Program

The company believes that its partners achieve two things: cost savings on disposal and enhanced sustainability practices. VLS’s program targets manufacturers and industries that consistently deal with damaged or outdated pallets.

“This initiative isn’t just about recycling pallets; it’s about creating opportunities,” explained Doug Dugan, Regional Vice President. “With this program, we’re addressing a pervasive waste problem and delivering eco-friendly, cost-effective alternatives to traditional disposal methods.”

Dugan continued, “It’s a game-changer for our partners and the environment alike.”

The overall goal of the program is to reduce carbon emissions and companies’ carbon footprint. The company says each recycled pallet contributes to cleaner energy production. “Every pallet we process contributes directly to a cleaner, more sustainable tomorrow,” said Chad Paul, Director of Sales. “It’s a simple, effective solution to a significant environmental challenge.”