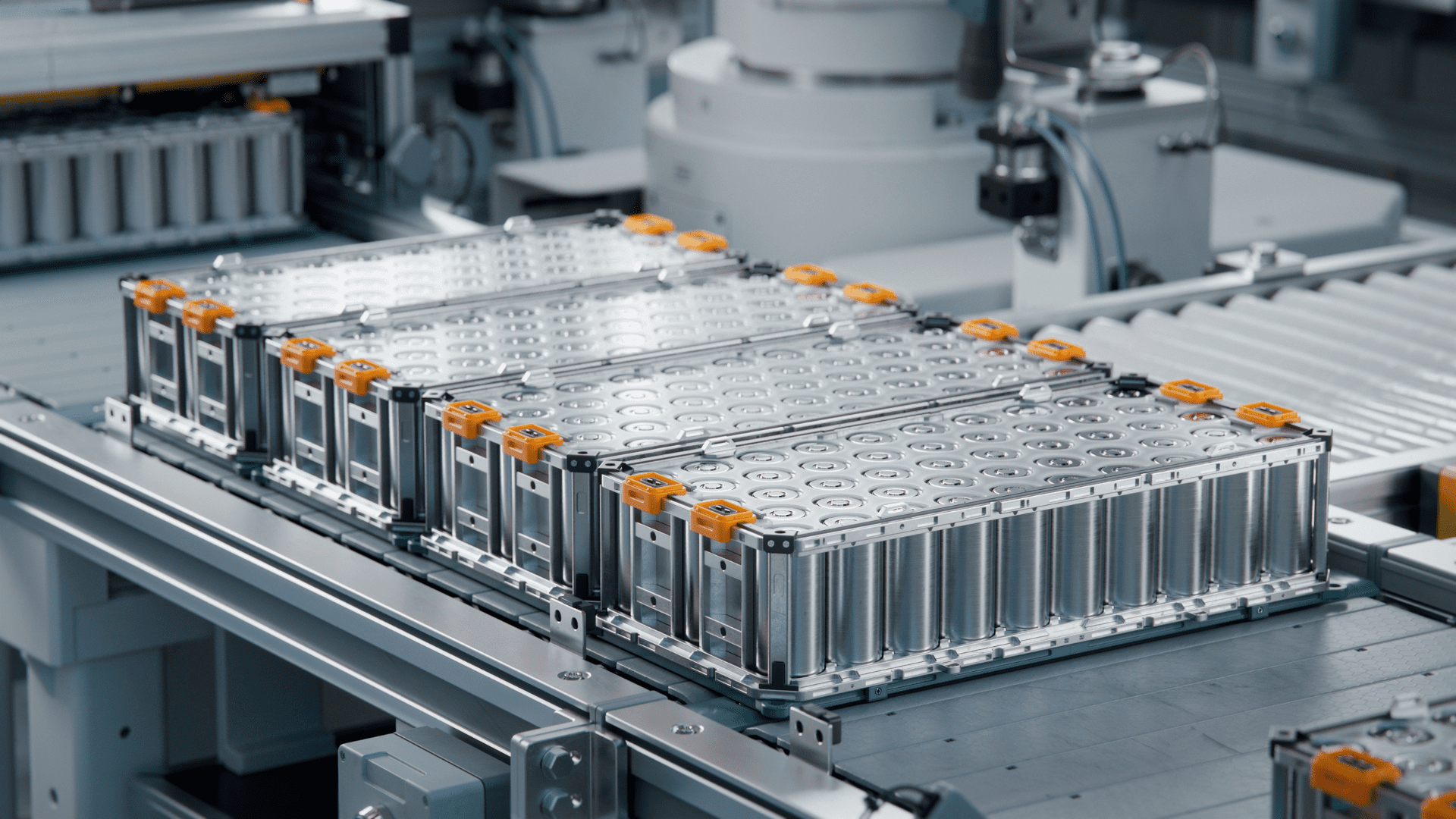

Toyota announced that Toyota Engineering & Manufacturing North America, Inc. (TEMA) was selected to receive $4.5 million in funding from the U.S. Department of Energy, Advanced Research Projects Agency-Energy (ARPA-E). The funding is part of the Catalyzing Innovative Research for Circular Use of Long-lived Advanced Rechargeables (CIRCULAR) Program, designed to support a circular domestic supply chain for electric vehicle (EV) batteries.

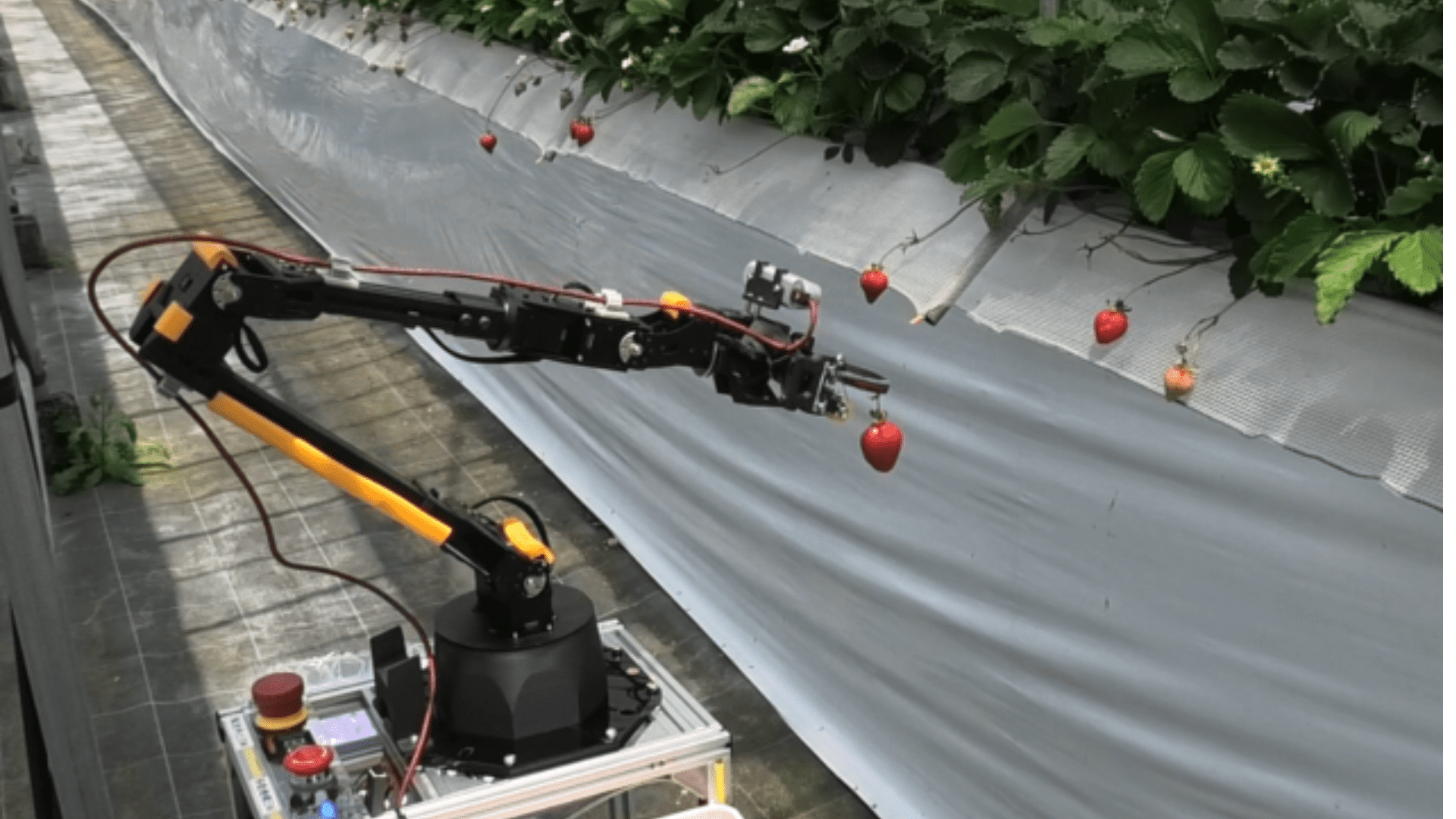

TEMA’s Toyota Research Institute of North America (TRINA) division will administer the project, which involves developing an Autonomous Robotic Disassembly Process for Applications in Battery Pack Circularity.

Several organizations are collaborating with Toyota for the project. They include Oak Ridge National Laboratory (ORNL), National Renewable Energy Laboratory (NREL), and Baker Hughes’ inspection technology product line, Waygate Technologies.

Reduce, Reuse, Recycle

This project aims to develop an industry-relevant template for a future 3R (Reduce, Reuse, Recycle) facility. The goal is to resolve the main bottlenecks in the circularity of the supply chain. These production delays include disassembly automation, data-driven classification, and addressing cell degradation.

Teams are working on developing tools and procedures to support that goal. These tools and procedures include an automated pack disassembly process, advanced diagnostic tools and protocols for module and cell 3R classifications, and a refabrication method for 3R cells into new energy systems.

Together, the innovations envision a scenario where lithium-ion batteries are reused before being recycled.

“As it stands, this project and program will highlight avenues for everyone to rethink their approach to battery circularity and help prioritize the extension of battery life, facilitate battery reuse, and reduce battery waste while unveiling the appropriate pathways to achieve such priorities,” said Nik Singh, principal scientist at TRINA. “This is only made possible by the collaboration between the exceptional teams comprised within this project group.”

A New Approach

A new approach is needed to extend the life of EV battery packs because scrap volumes are expected to increase in the coming years. The new approach must pave the way for a more sustainable, circular battery supply chain.

“We will generate processes to streamline reusing and refurbishing valuable battery cells and modules from end-of-life packs without having to scan every single battery pack every single time,” said Marm Dixit. Dixit is co-leading ORNL’s contributions to the project. “By extending the life of the battery components, we reduce their total emissions per mile. That’s a big deal for the role EVs can play in the energy transition.”