A research group led by Chalmers University of Technology in Sweden developed a silk thread with promising properties for generating electricity in textiles. This means that an ordinary sweatshirt or sweater could one day charge a device. At least, that’s what researchers envision.

Previously, the development of this degree was met with challenges, mostly because of the lack of materials that both conducted electricity and made a worthy piece of fabric.

Conductive Threads

Ordinary threads are coated with a conductive plastic material. Chalmers University said in a press release, “Thermoelectric textiles convert temperature differences, for example, between our bodies and the surrounding air into an electrical potential.” Our everyday lives could greatly benefit from this. Connected to sensors, the textiles power devices without batteries. The researchers explained that these sensors could measure our movements or monitor our heartbeat. Since the textiles are on our bodies, they must take extreme measures to ensure safety and flexibility.

Mariavittoria Craighero is a doctoral student at Chalmers University of Technology’s Department of Chemistry and Chemical Engineering. “The polymers that we use are bendable, lightweight, and easy to use in both liquid and solid form,” she said. ” They are also non-toxic.”

Researchers used the same method in previous studies within the same research projects. Previously, the thread contained metals to maintain its stability in contact with air. There have been advances since then. For example, they manufacture the threads with only organic, carbon-based polymers. The researchers developed a new type of thread for this study with “enhanced electrical conductivity and stability.”

“We found the missing piece of the puzzle to make an optimal thread – a type of polymer that had recently been discovered. It has outstanding performance stability in contact with air, while at the same time having a very good ability to conduct electricity,” said Craighero. “By using polymers, we don’t need any rare earth metals, which are common in electronics.”

Put to the Test

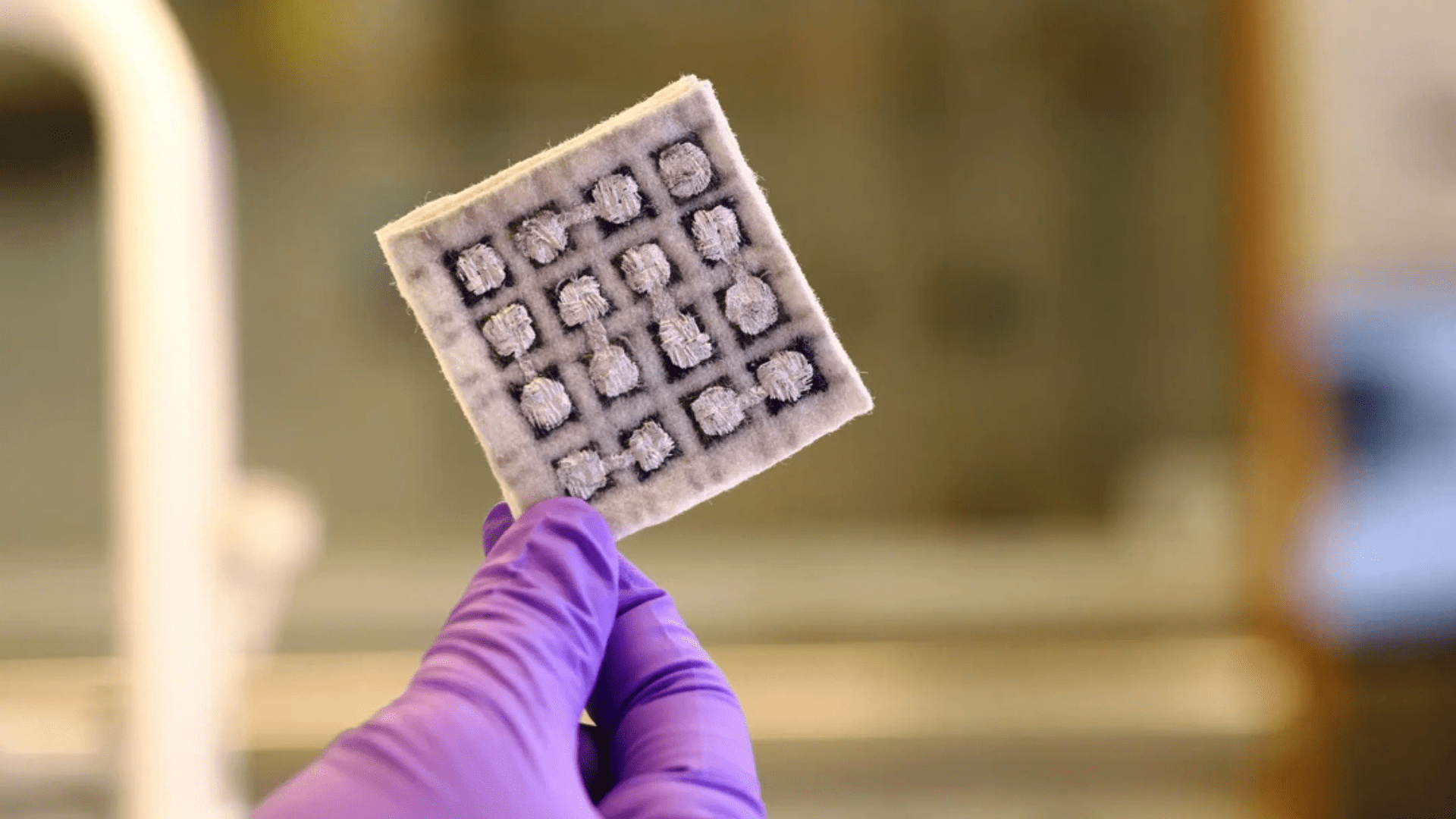

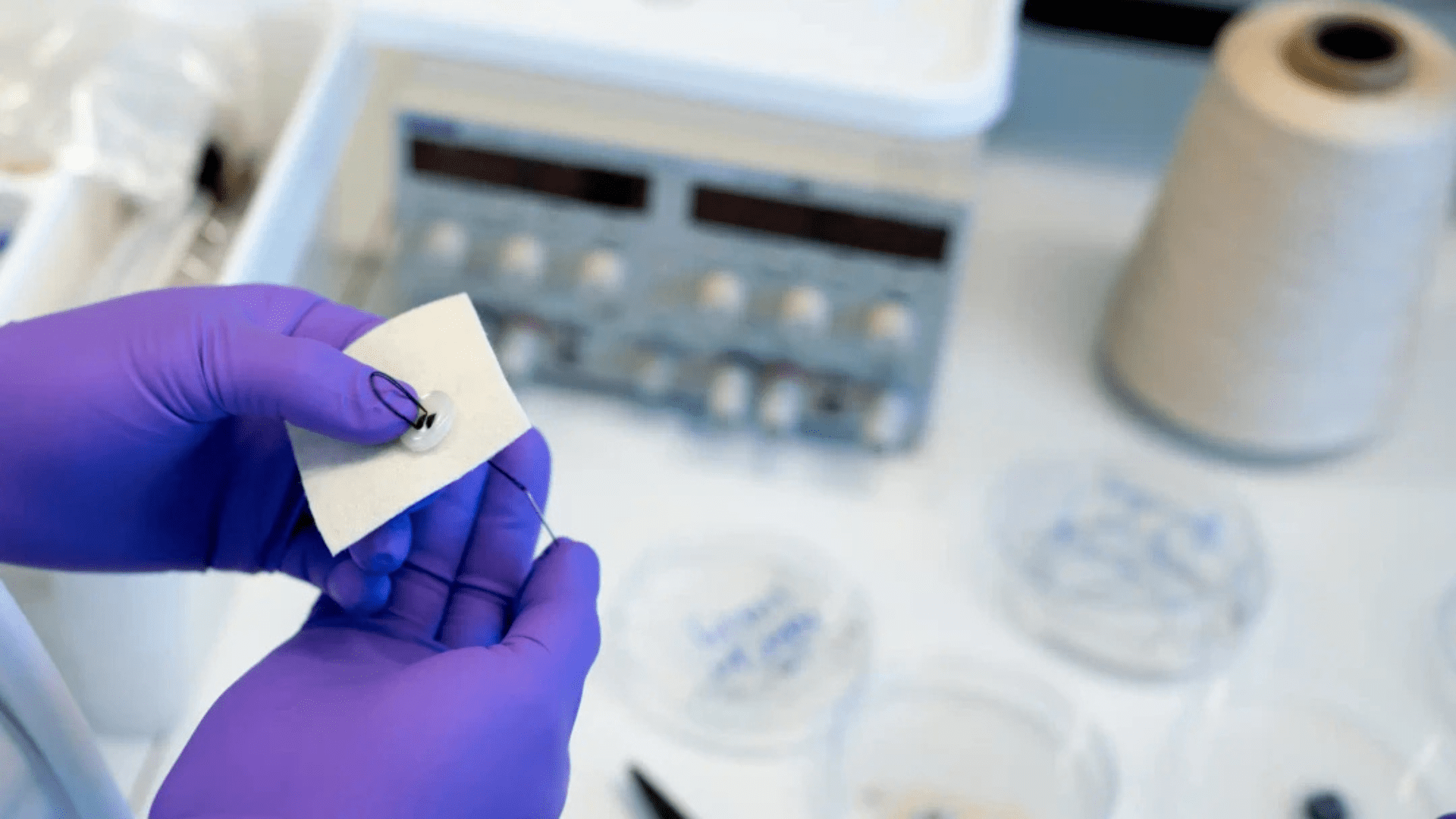

Researchers manufactured two thermoelectric generators to demonstrate how the threads can be used. One was a button sewn with the thread, and the other was a piece of textile with sewn-in threads. When the researchers placed the thermoelectric textiles on hot and cold surfaces, they could observe how the voltage changed. “As an example, the larger piece of fabric showed about 6 millivolts at a temperature difference of 30 degrees Celsius,” the press release said. “In combination with a voltage converter, it could theoretically be used to charge portable electronics via a USB connector.”

The researchers also proved that the thread lasts for at least a year and is machine washable.

“After seven washes, the thread retained two-thirds of its conducting properties,” said Craighero. “This is a very good result, although it needs to be improved significantly before it becomes commercially interesting.”

The thermoelectric fabric and button cannot be produced efficiently outside the lab environment today.

“We have now shown that it is possible to produce conductive organic materials that can meet the functions and properties that these textiles require. This is an important step forward,” said Christian Müller, a Chemistry and Chemical Engineering Professor at Chalmers University of Technology. “There are fantastic opportunities in thermoelectric textiles, and this research can be of great benefit to society.”