We are one step closer to a future where injuries heal faster, meat is lab-grown, and diseases are cured more effectively. The innovative work by Dr. Hao Liu from ETH Zurich made that future a possibility. Using laser technology, Liu created microscopic structures that mimic the natural architecture of human tissues.

Laser Tech, Lab Grown

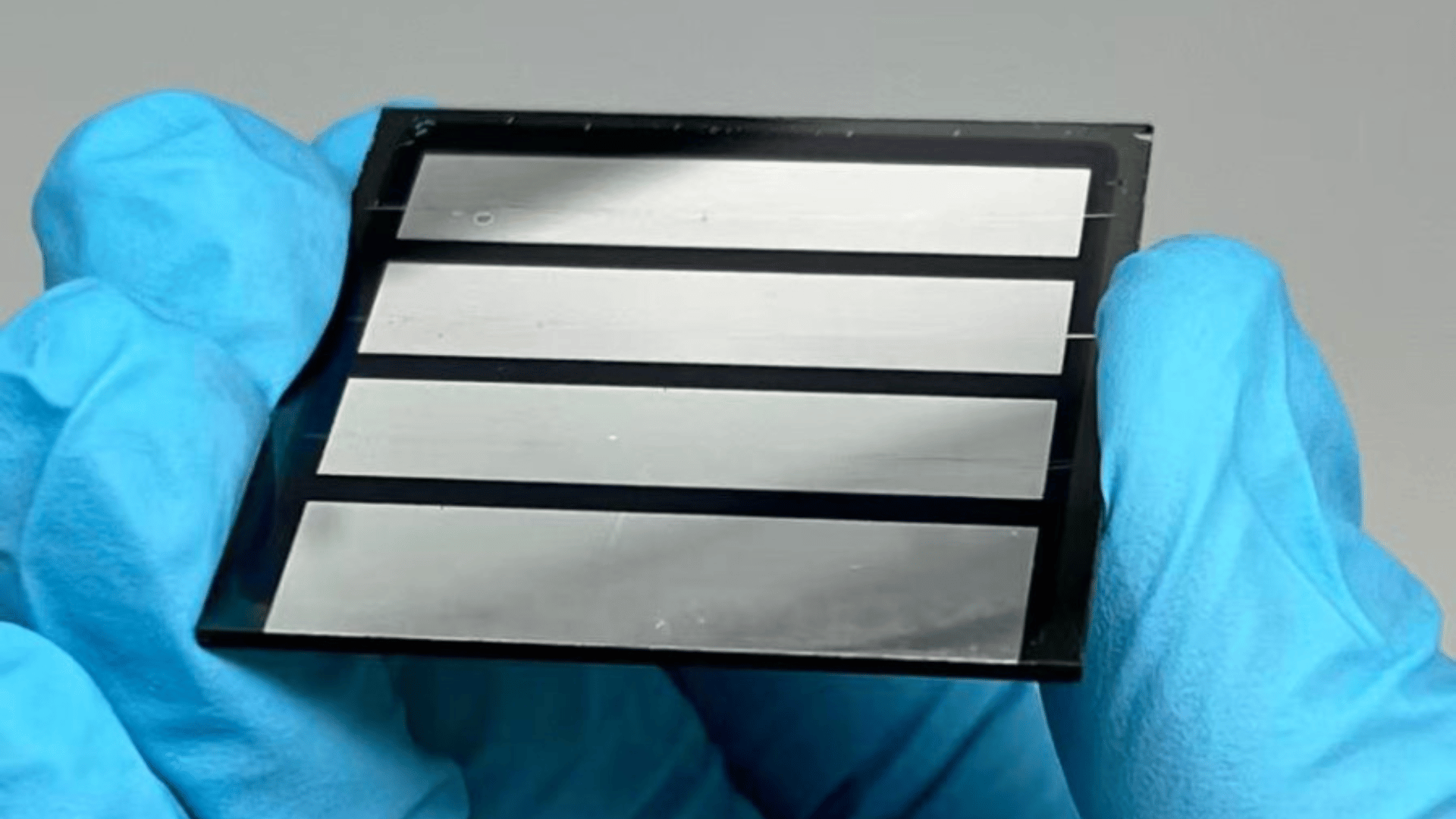

The structures are made from a special gelatin type, which serves as scaffolds for growing cells. Liu and his team carefully control the laser technology to create “highly aligned microfilaments.” These filaments replicate the precise structures in tissues like muscles, tendons, and nerves.

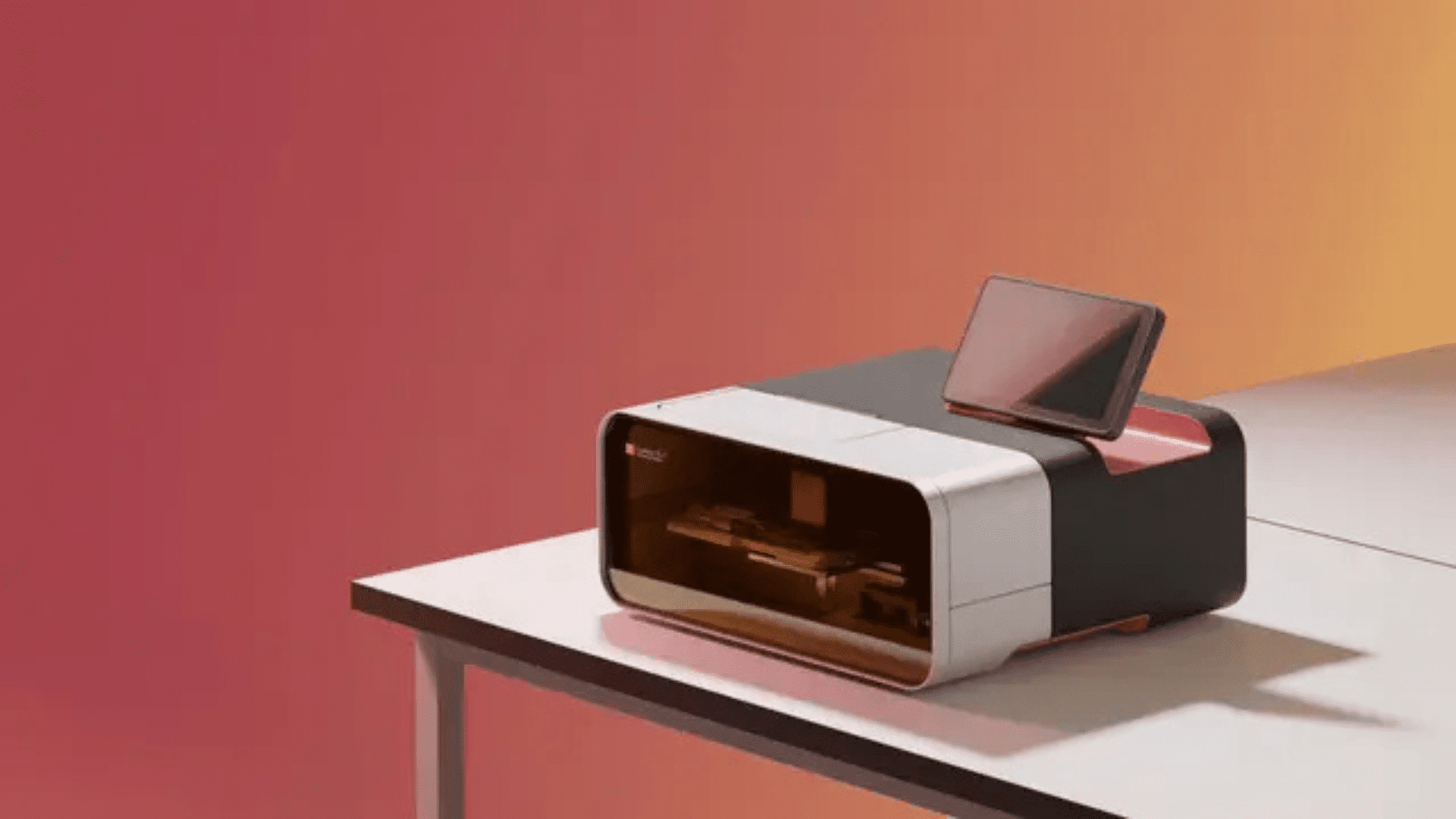

The researchers created a bioprinter to develop biological tissues with microfilament structures. Now, Liu wants to bring this to market. “Our aim is to create human tissue models for high-throughput drug screening and other applications,” Liu said.

Researchers use the bioprinter to create 3D scaffolds to replicate natural tissues made in a lab. The scaffolds are a template for growing cells, resulting in perfectly structured tissue.

Utilizing Artificial Tissues

The innovative lab tissues have several uses, including surgical replacements, medical research, and food production. Additionally, they can repair damaged nerves, model diseases for drug testing, and produce lab-grown meat. First, Liu printed tissue scaffolds and then used a novel method to create highly aligned, fine filaments. When exposed to laser light, he utilized a light-sensitive gelatin that transforms from a liquid to a solid.

Liu said, “Where we expose it with a laser, it solidifies into hydrogel. Wherever the laser can’t reach, the gelatine remains liquid.”

Within the hydrogel, he successfully created microfilaments. These microfilimanets were comparable in size to the fibrous components in natural tissues, Subsequently, he cultivated cells on this scaffold to generate aligned tissue structures.

“The optical phenomenon that creates the filament microstructures in the gel has long been known to physicists and material scientists,” Liu said. “But it hadn’t yet been used in biology; we’re the first.”

Utilizing this printing method, the team produced tissue constructs similar to muscle, tendon, nerve, and cartilage tissues. ETH Zurich has patented this technology.