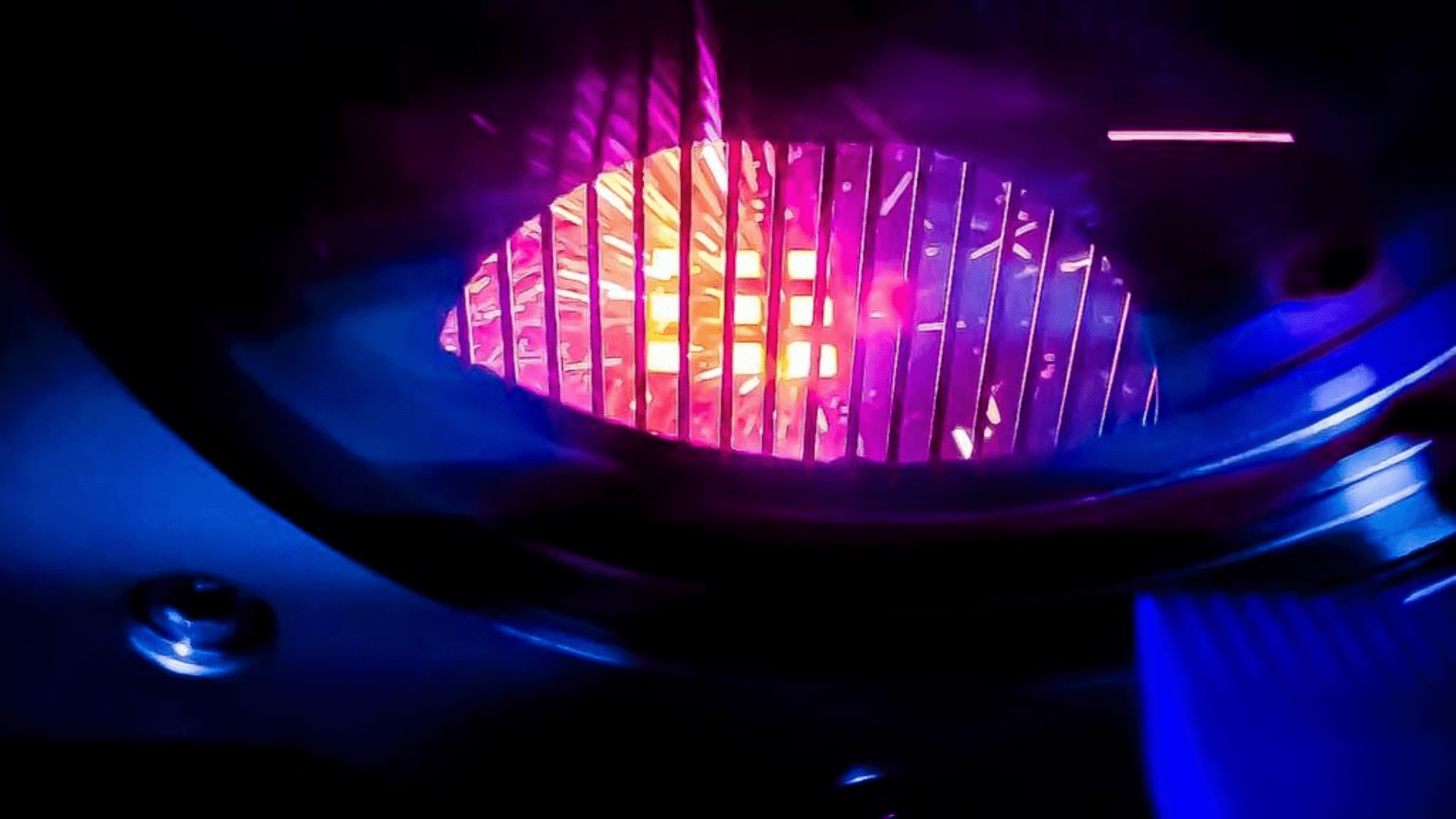

U.S. Researchers have developed a 3D-printed, crack-free alloy that can withstand extreme temperatures without melting. They aim to use this substance for airplanes, specifically turbine blades. The lightweight alloy can stay strong under temperatures over 2,400 degrees F. Researchers at Oak Ridge National Laboratory (ORNL) and the National Energy Technology Laboratory (NETL) achieved the milestone.

Researchers expect the alloy to enable 3D-printed turbine blades to handle extreme temperatures while reducing the carbon footprint of gas turbine engines, such as the ones used in airplanes.

“No one has been able to develop and print alloys with such a high melting temperature and low density without cracks before,” said ORNL’s Saket Thapliyal. A 3D printer at the ORNL’s Manufacturing Demonstration Facility was used to print the unusual crack-free alloy.

Years in the Making

A few years back, ORNL demonstrated a crack-free superalloy made of cobalt and nickel. It remained crack-free and resistant to extreme heat, making it suitable for metal-based 3D printing applications. However, the latest crack-free alloy is more efficient than the previous one. Researchers fine-tuned the electron beam melting process to print test parts for the novel alloy.

“This is significant,” said Thapliyal. “We’re making something lighter that can hold its structural integrity at ultra-high temperatures.”

ORNL is the world’s premier research institution. Almost a year ago, it teamed up with the National Energy Technology Laboratory to explore carbon management and strategies for sustainable energy transitions in the Appalachian region. The two companies’ partnership also includes economic development in this region.

The two organizations agreed to develop modern technologies. For example, they’re working on advanced manufacturing technologies emphasizing decarbonizing the energy, industrial, transportation, and building sectors.