A consortium led by Airbus has performed the first metal 3D printing aboard the International Space Station (ISS).

Explore Tomorrow's World from your inbox

Get the latest science, technology, and sustainability content delivered to your inbox.

I understand that by providing my email address, I agree to receive emails from Tomorrow's World Today. I understand that I may opt out of receiving such communications at any time.

The printing created a small S-shaped curve out of liquefied stainless steel. According to the ESA, the test line shows that the printer will soon start manufacturing usable materials.

On January 30th of this year, the metal 3D printer flew to the ISS aboard the Cygnus NG-20 mission, which was launched aboard a SpaceX Falcon 9 rocket. The goal of the project is to one day repurpose pieces of old satellites using similar 3D printers and to aid in creating a circular economy in space.

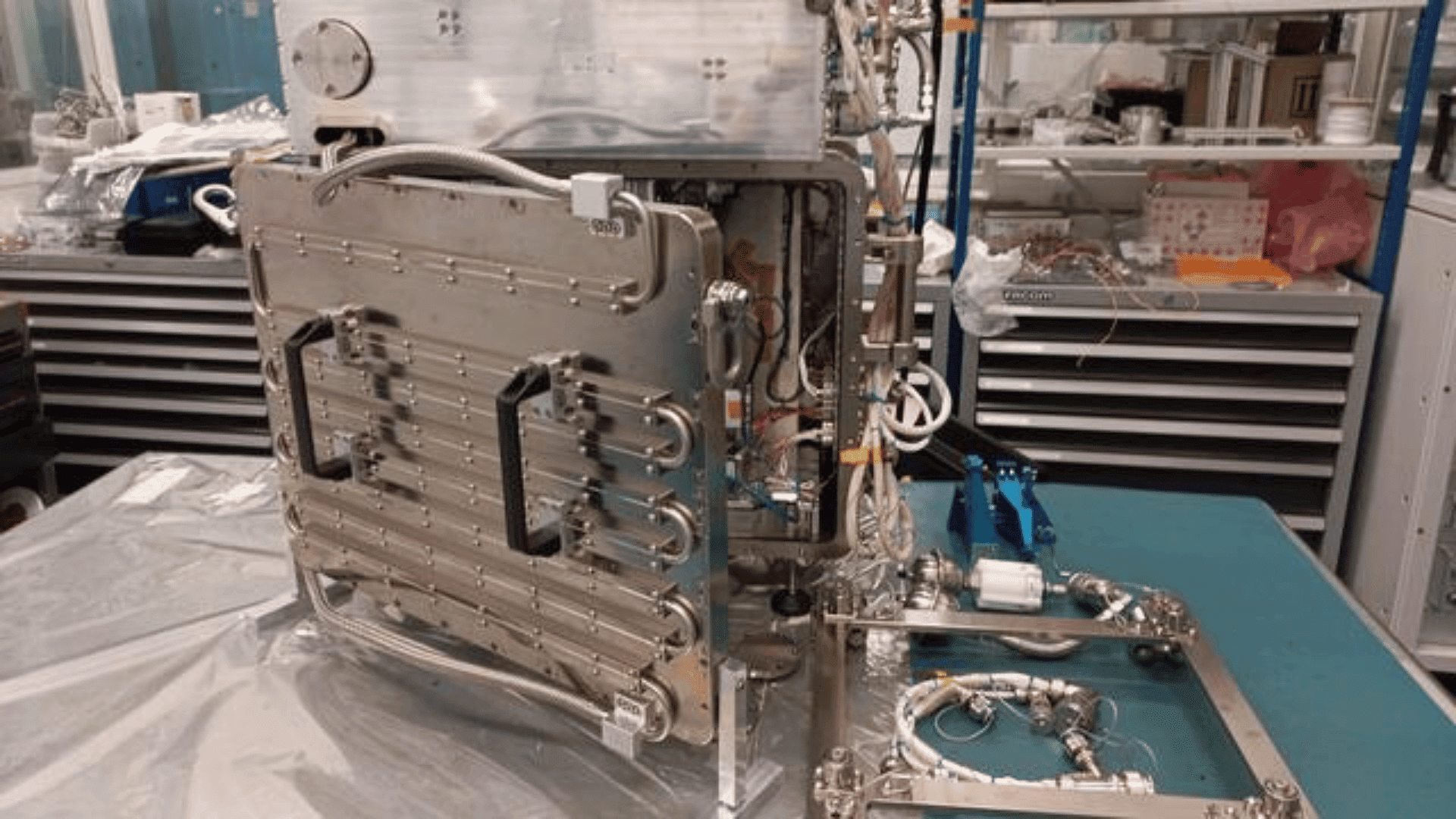

Though plastic 3D printers are already used aboard ISS, metal 3D printers present a greater challenge as they require lasers that heat the metals to a high enough temperature to be liquified. Therefore, the metal printer aboard the ISS is contained inside a fully sealed box that prevents excess heat or fumes from escaping.

“The success of this first print, along with other reference lines, leaves us ready to print full parts in the near future,” ESA technical officer Rob Postema explained in a press statement. “We’ve reached this point thanks to the hard efforts of the industrial team led by Airbus Defence and Space SAS, the CADMOS User Support Centre in France, from which print operations are overseen from the ground, as well as our own ESA team.”

The machine feeds stainless steel wire into a chamber, where it’s heated by a high-power laser. The laser melts the steel and allows the printer to shape it. The printing process is controlled from the ground, and the printer will next be tasked with creating four shapes that will be sent to Earth for analysis.

The team behind the research also hopes that astronauts could eventually 3D print parts required in orbit. This would save on launch costs, as tools typically need to be launched to the ISS aboard a cargo mission.

“Two of these printed parts will be analyzed in the Materials and Electrical Components Laboratory at ESTEC in the Netherlands to help us understand whether prolonged microgravity has an effect on the printing of metallic materials,” ESA materials engineer Advenit Makaya explained in the statement. “The other two will go to the European Astronaut Centre and the Technical University of Denmark, DTU.”