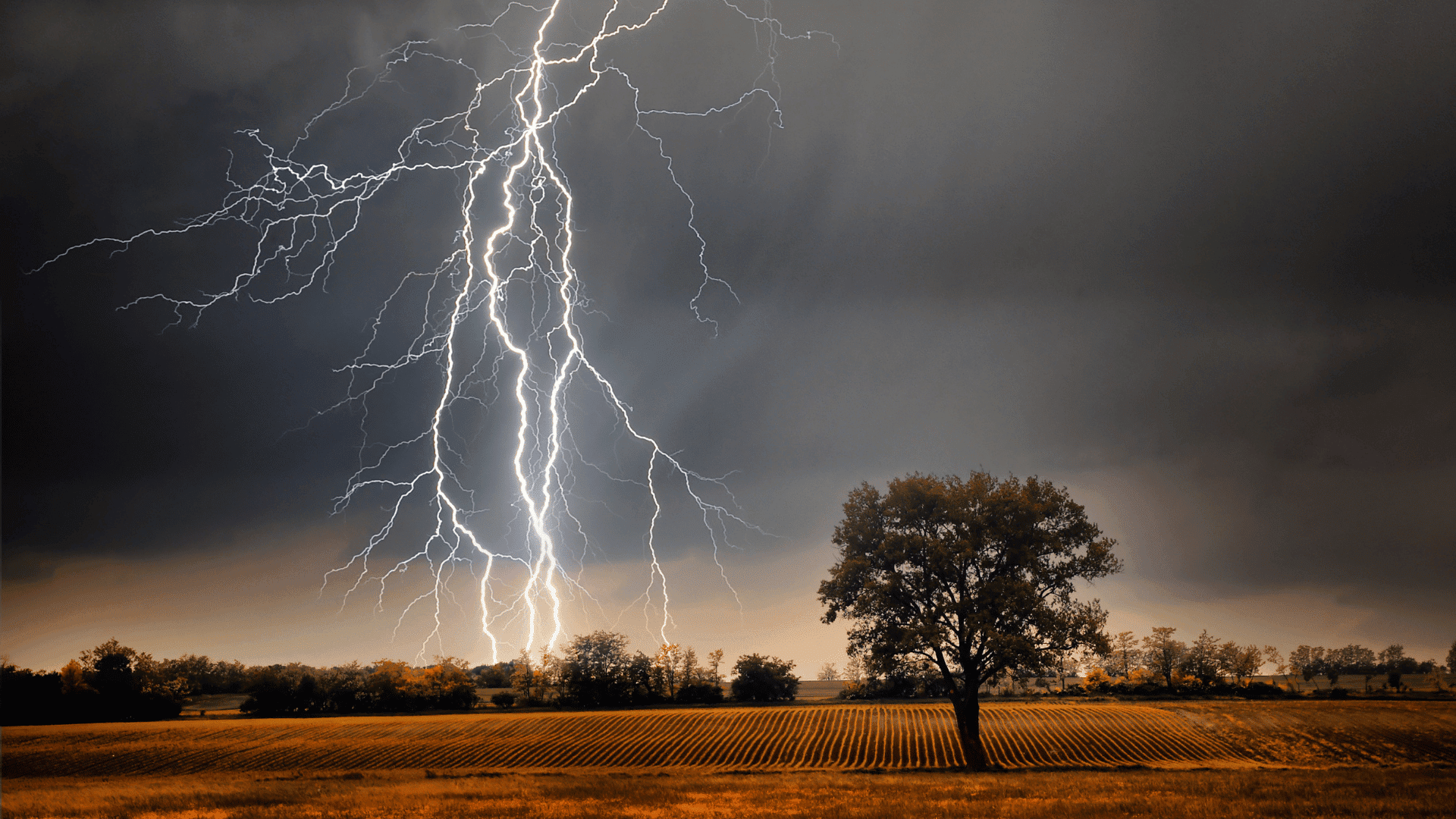

As winter begins to turn to spring and cloudy days begin to turn to sunshine, snow begins to turn to rain. Although that can be an exciting change for those already breaking out their spring wardrobe, it can also be a very easy time of year to get caught in the rain. Luckily, your trusty umbrella keeps anything from raining on your parade.

Modern umbrellas are typically made using a hand-assembly process that only differs slightly between a stick umbrella and a collapsible umbrella. The collapsible umbrella is the most recent innovation in umbrellas and this is where the umbrella will collapse into a convenient travel size.

The stick umbrella will typically begin as a shaft of either a piece of wood, aluminum, or steel. Wood shafts, typically made from trees like Rowan wood, are typically made using wood-shaping machines such as a turning machine or lathe. Plastic or metal shafts, on the other hand, will be drawn or extruded into the desired shape.

The ribs and stretchers are assembled first, these are the pieces of metal that run underneath the canopy of the umbrella. The ribs are attached to the shaft by fitting into a top-notch and the stretchers are connected to the shaft using a plastic or metal runner. The runner is the piece of the umbrella that will move along the shaft and allow the umbrella to open and close.

Then the ribs and stretchers are connected to each other using a joiner, which is a small jointed metal hinge. Then two catch springs are placed along the shaft where the umbrella will be able to lock in the open or closed positions.

Finally, the canopy is hand sewn to include individual panels for the umbrella’s ribs. Each panel is hand-cut separately and then sewn into the original canopy piece. The tip of the umbrella that passes through the canopy is covered with a metal piece that has been glued in place. The handle of the umbrella is then added and, after it has been packaged, it goes from the production line to protecting you from a storm.